JU88/BF109 Mistel

JU88/BF109 Mistel

By Rob Bedford

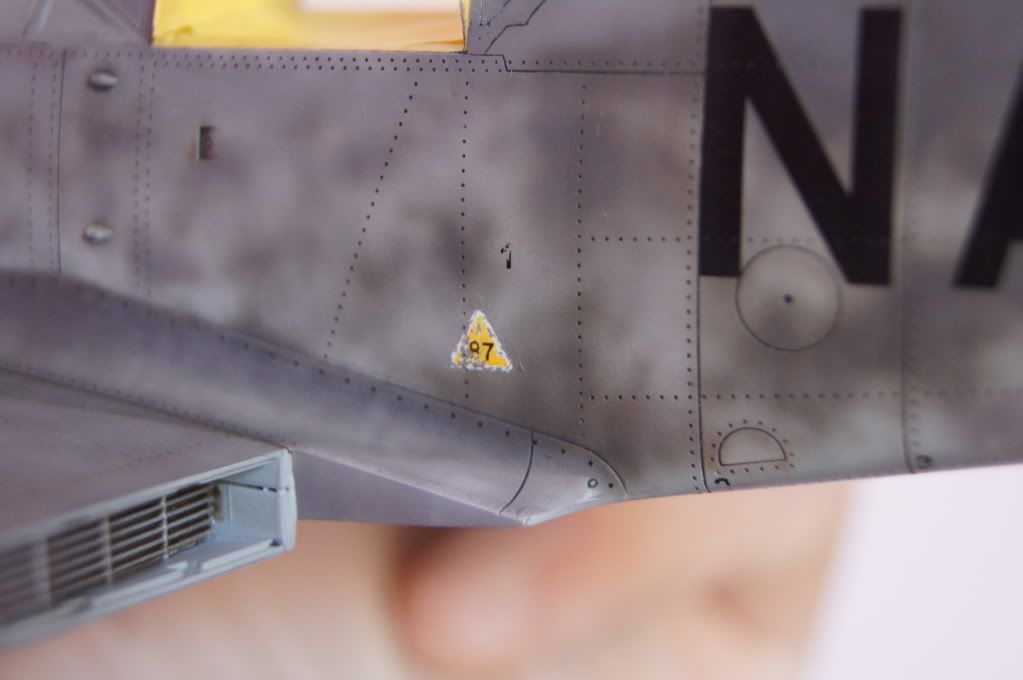

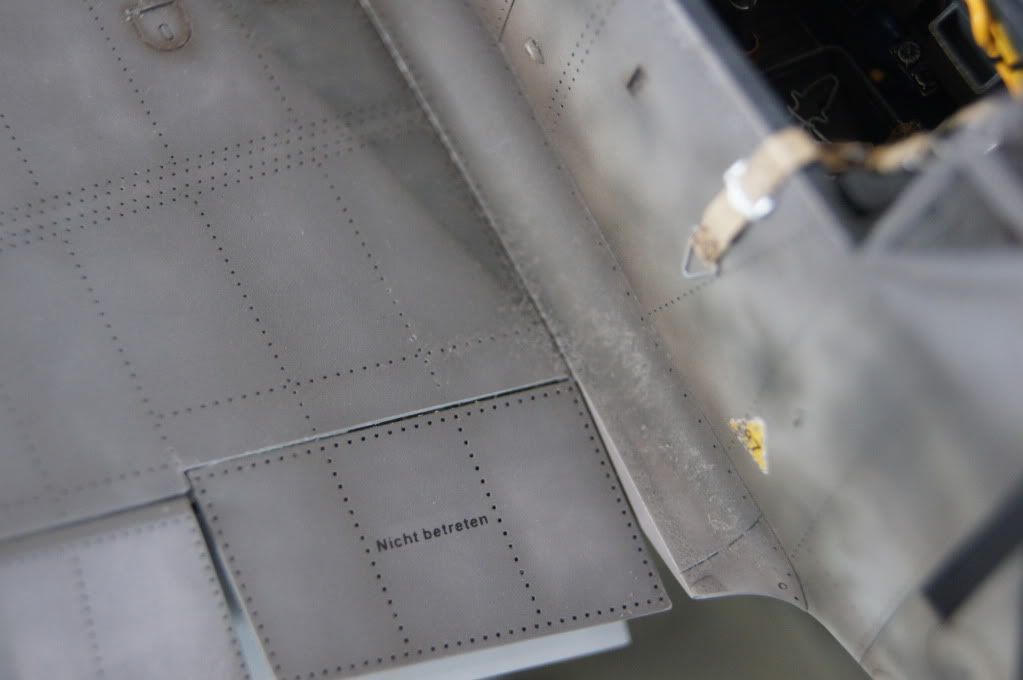

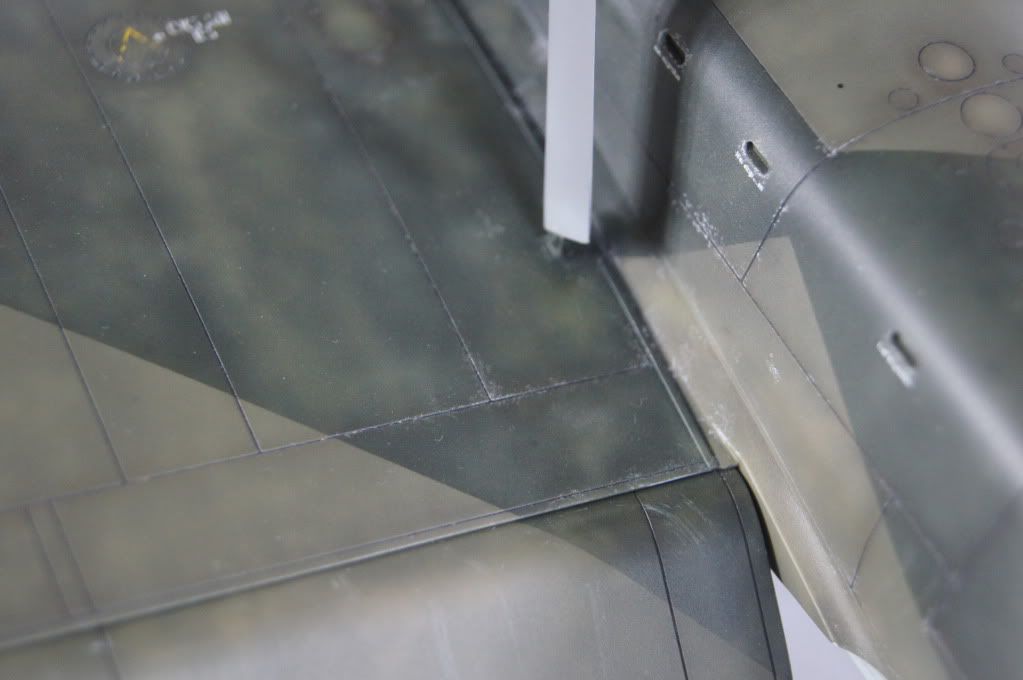

Upperside BF109 Gunze RLM 74/75, underside RLM 76. With same post shading as JU88. Cocpit colour was Tamiya RLM 66.

Aires JU88 wheels (AIRE2086)

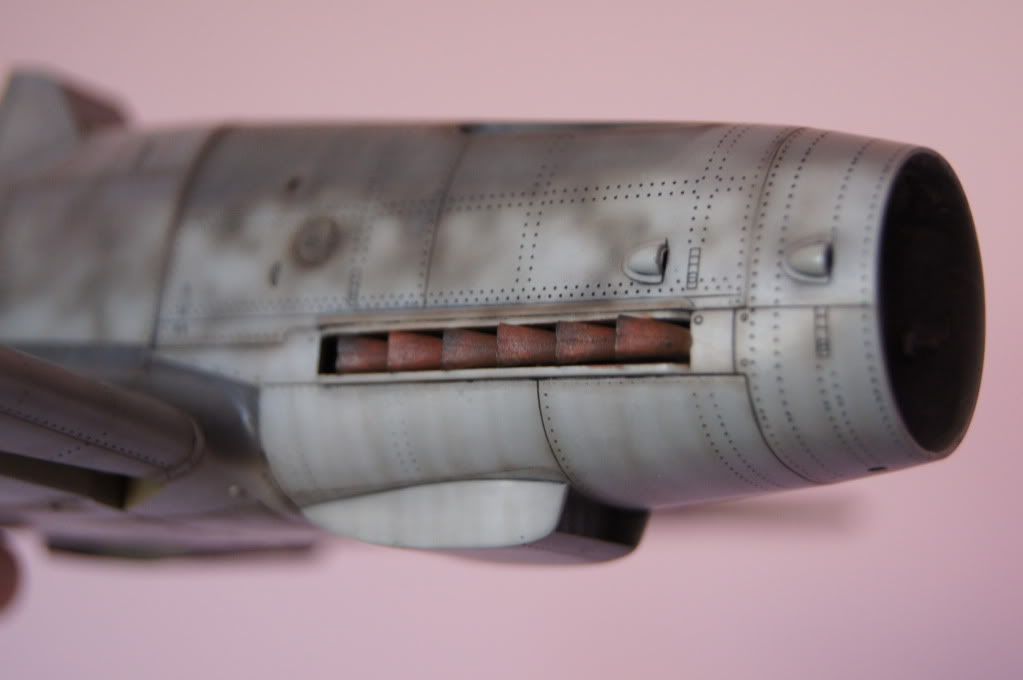

Quickboost JU88 exhausts (QB32059)

Eduard JU88 exterior (ED32224)

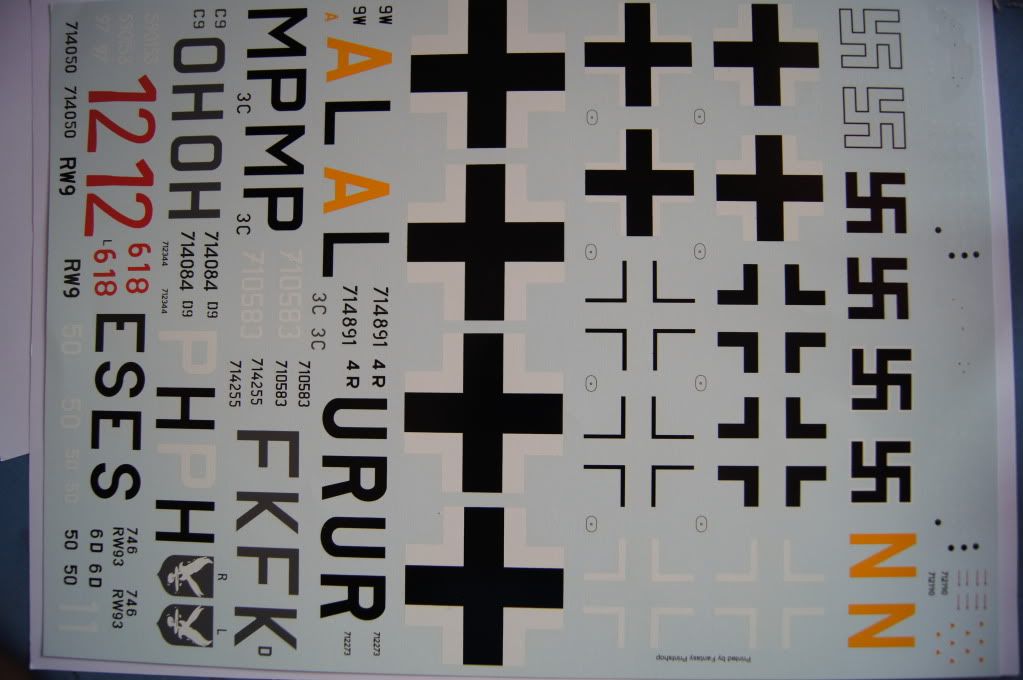

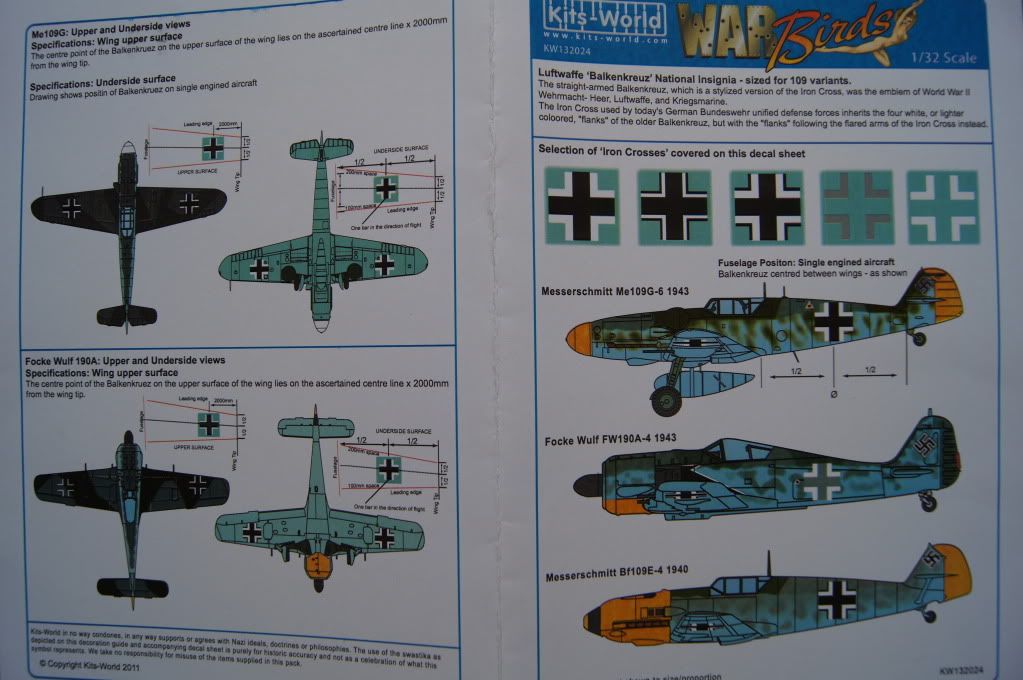

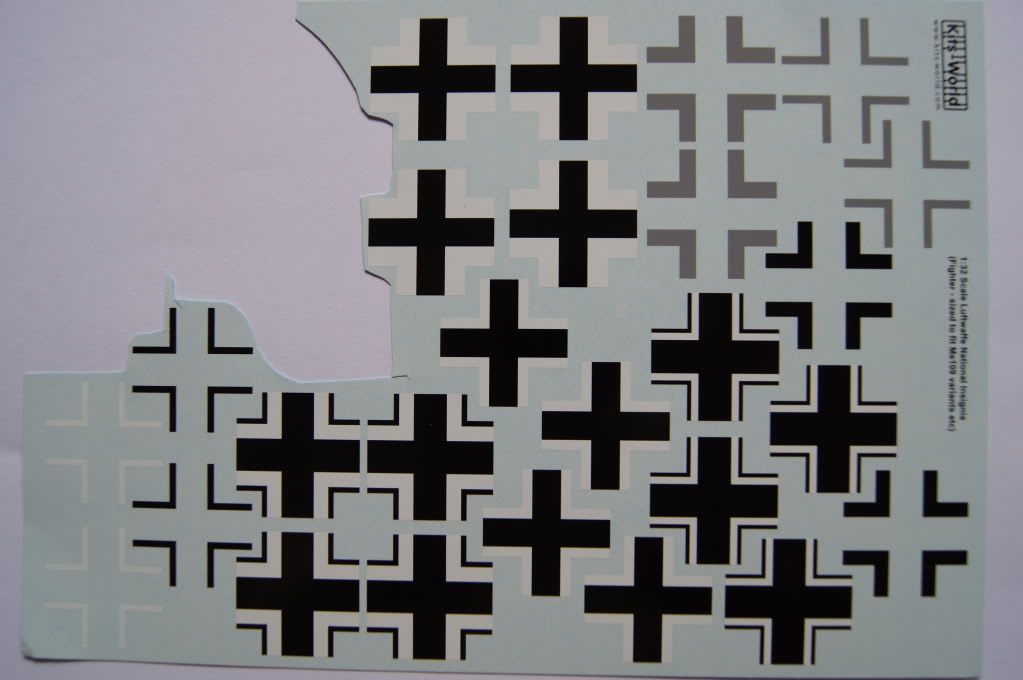

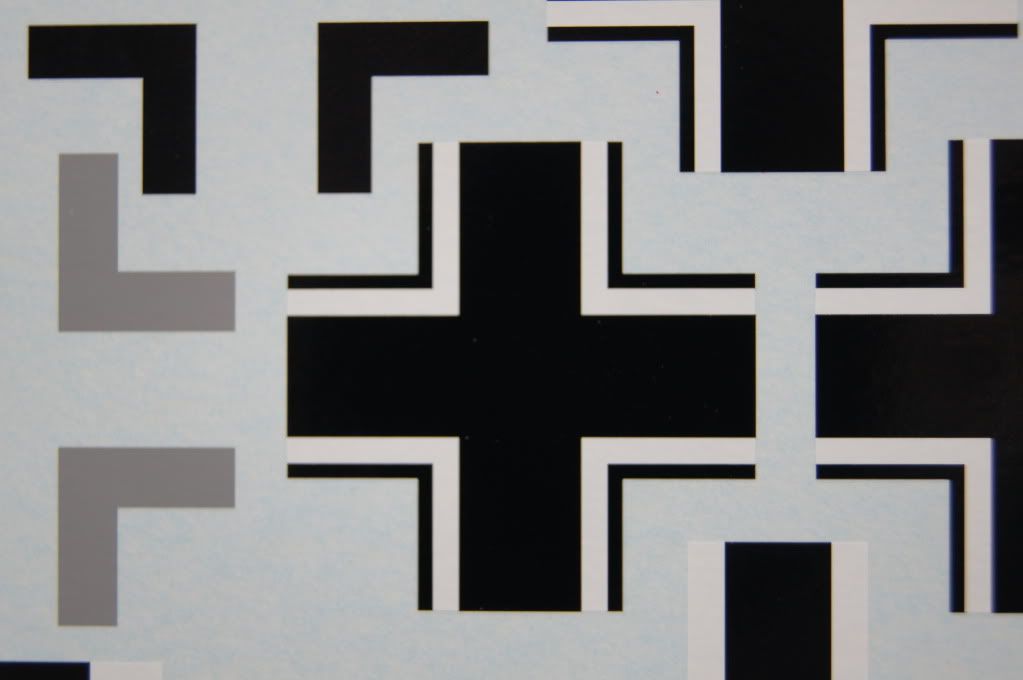

Kits World decals (KW32024) Only used some of these.

Airdoc decals (AIRM3213) Only used two of the German croses

Aires BF109 wheels (AIRE2138)

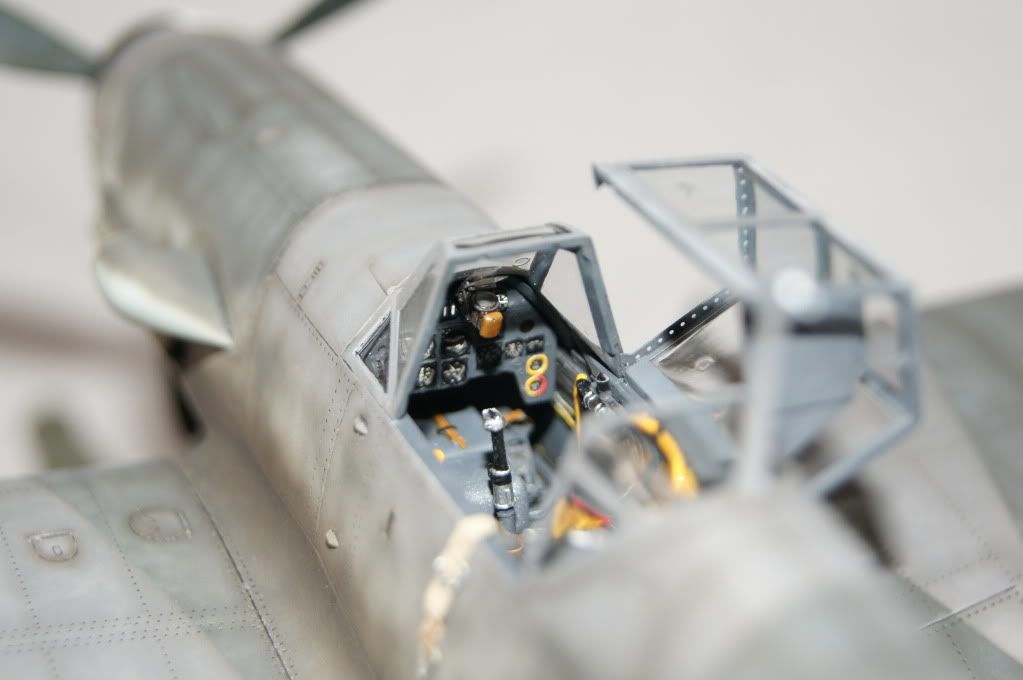

Aires BF109 cockpit set (AIRE2144)

Quickboost BF109 propllers (QB22095)

Cockpit details were picked out with Vallejo Model Air acrylics.

Also the very heavy aims detail set for both my mistel's.

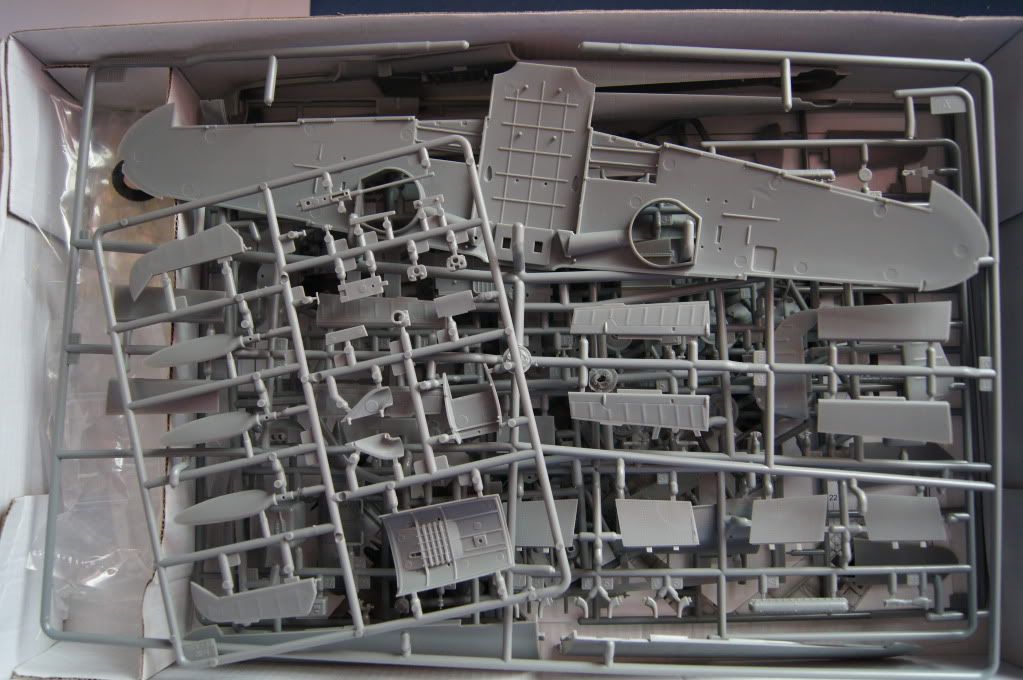

These parts were neatly packed within the box with bubble wrap and lots of foam. So don't worry it will not look like this when you open the box.

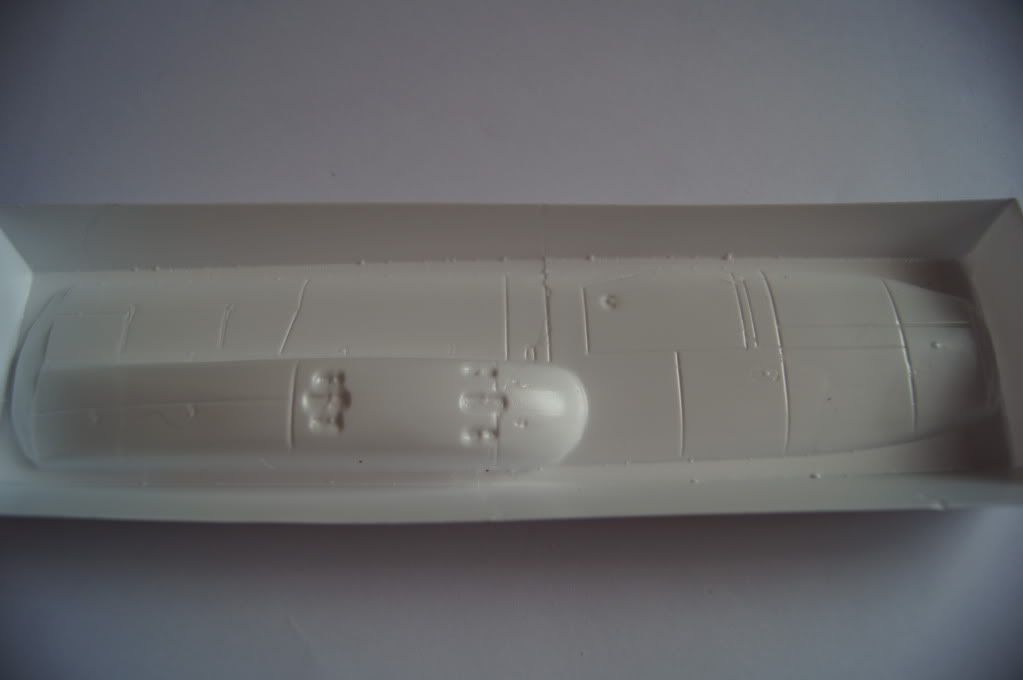

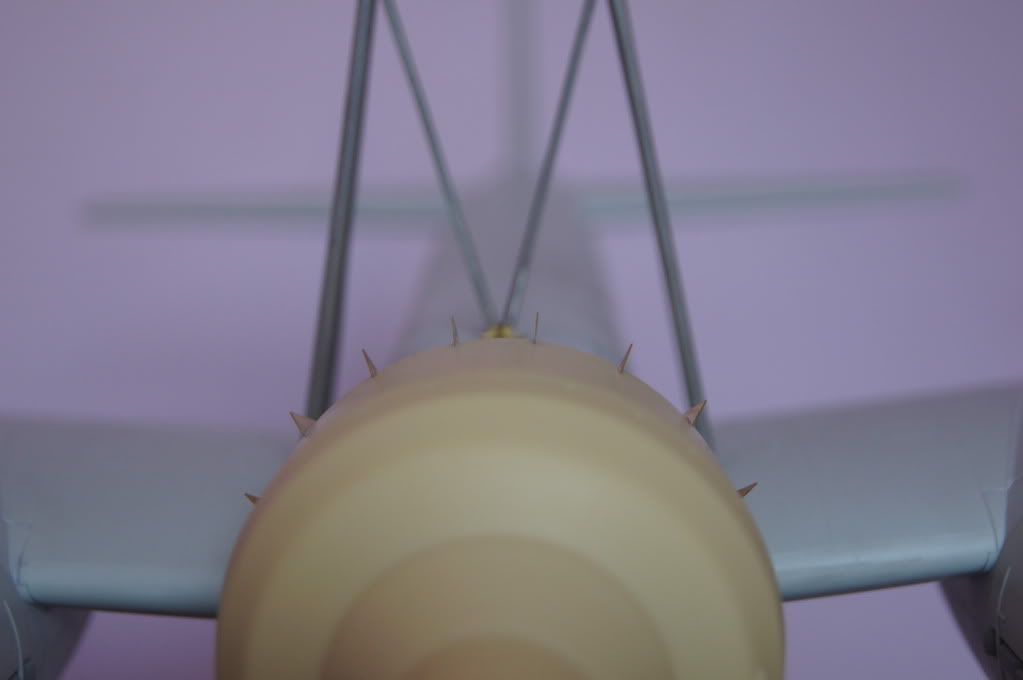

The heavy warhead for the mistel 1. This is equal to holding 3 full pots of tamiya paint in your hand. Hope i've got some extra stong glue to hold this on, i think superman could help me with this, lol.

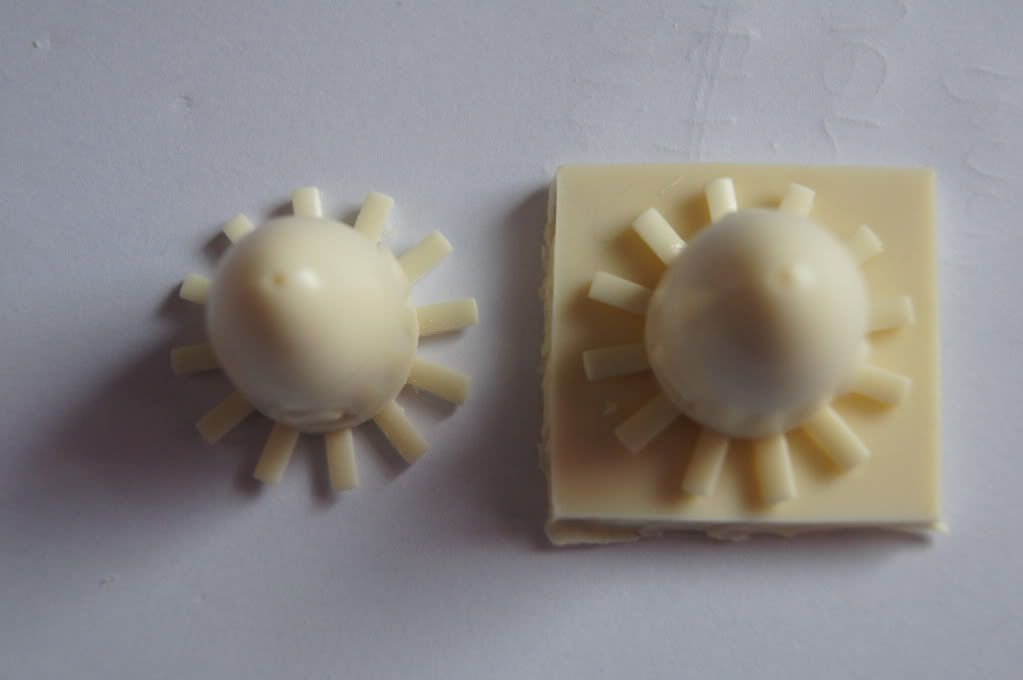

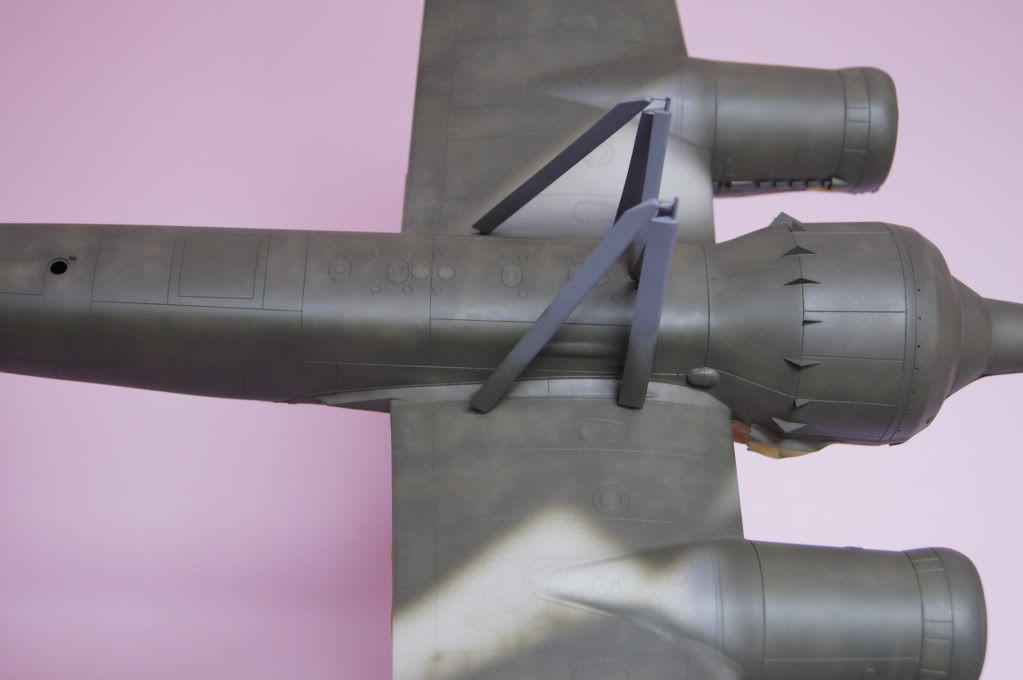

Both engine nacells + engines for the JU88G-1.

It's for the underbelly, but i don't know whether for the g or a version of the ju88 .

.

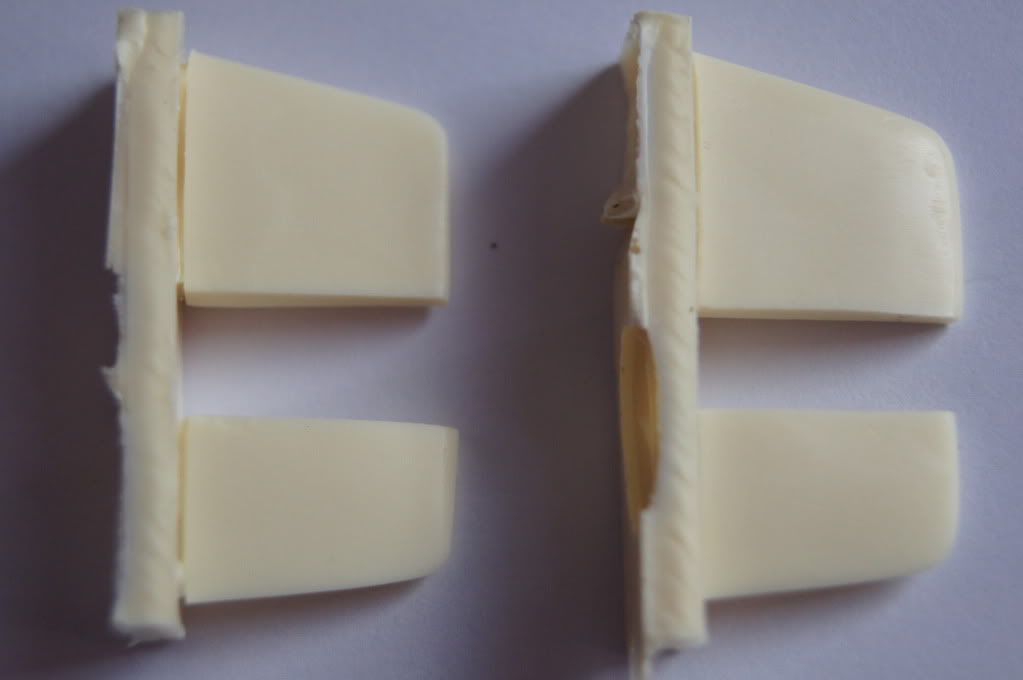

G-1 Rudder.

I've cut one of the casting blocks off.

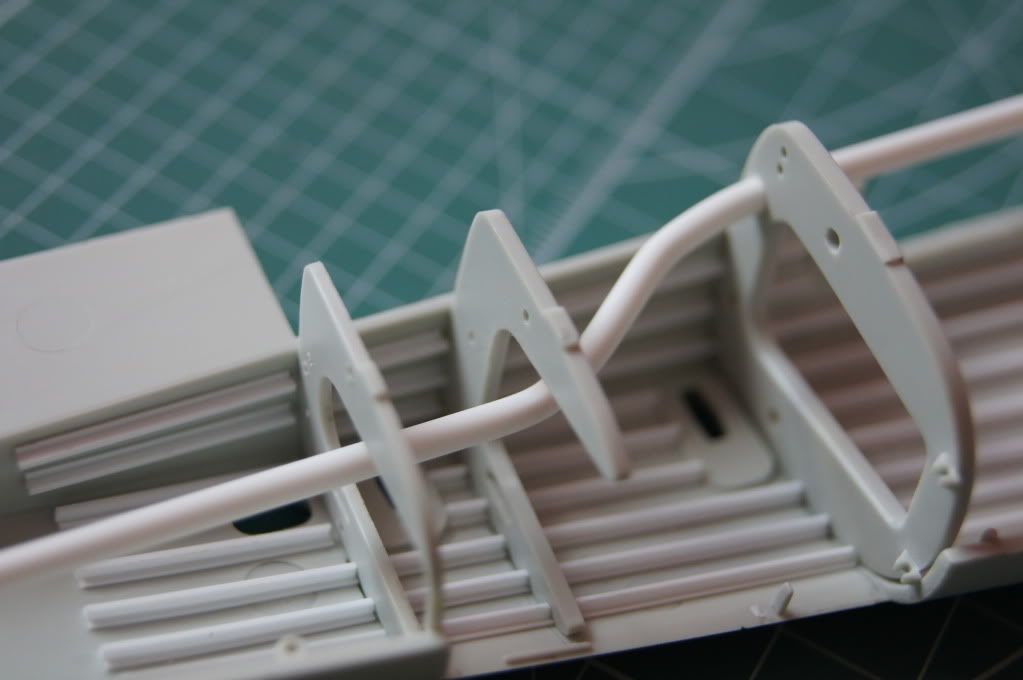

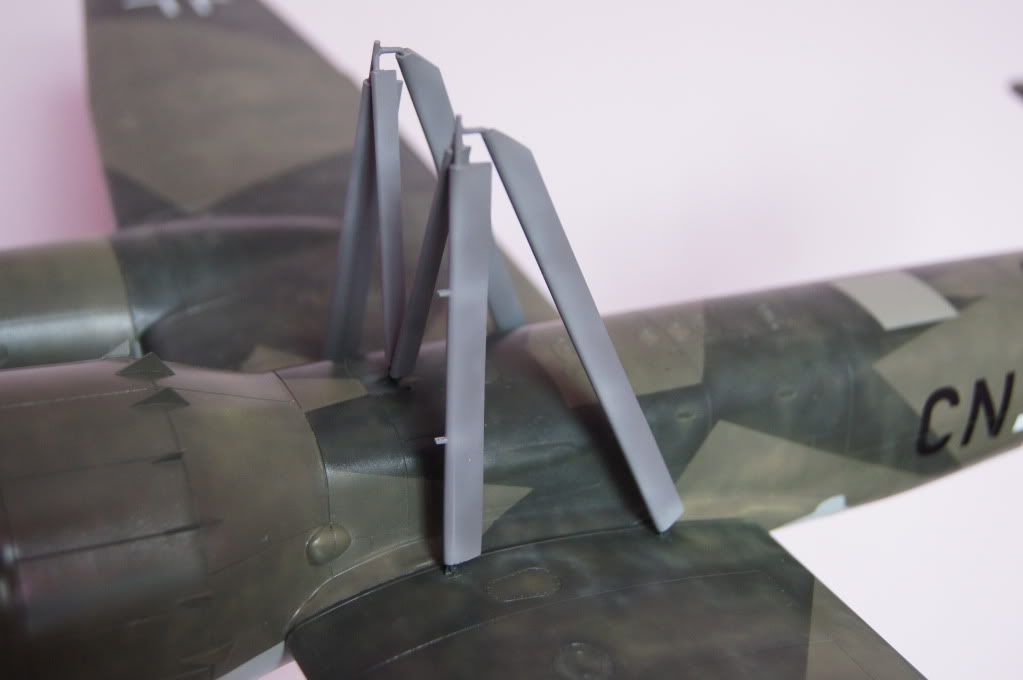

2 sets of bracings in, cast in white metal.

G-1 Extended wing tips.

Because of the G-1 extended wing tips, aims have provided new extended ailerons for the G-1.

G-1 engine parts.

Again i have cut one of the casting blocks off. It was very easy to do.

G-1 nose.

G-1 bits and bobs, i will go into more detail later.

G-1 extended elevators and rear wing.

Vac form top part of fuselage spine for the G-1.

Vac form canopy for the G-1.

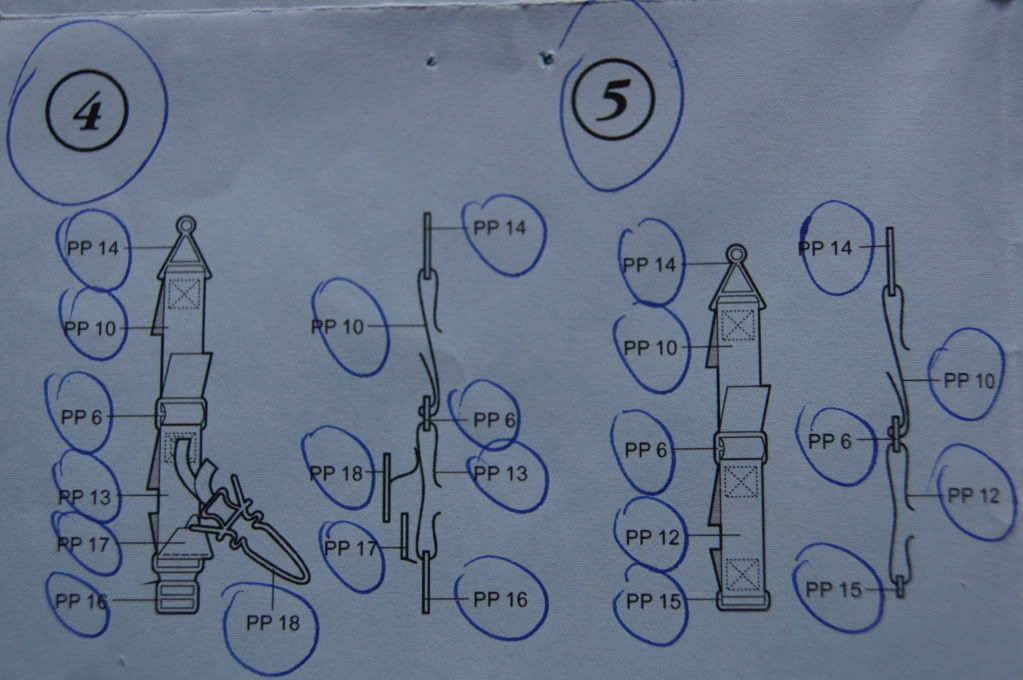

Antenna parts to make a night fighter version of the G-1.

Very large decal sheet.

Smaller decal sheet. I was a bit worried about not being able to find the right decals, well problem solved. Aims do all the decals for nearly every mistel from 1/72 to 1/32. YESSSSSSSSSSSSS.

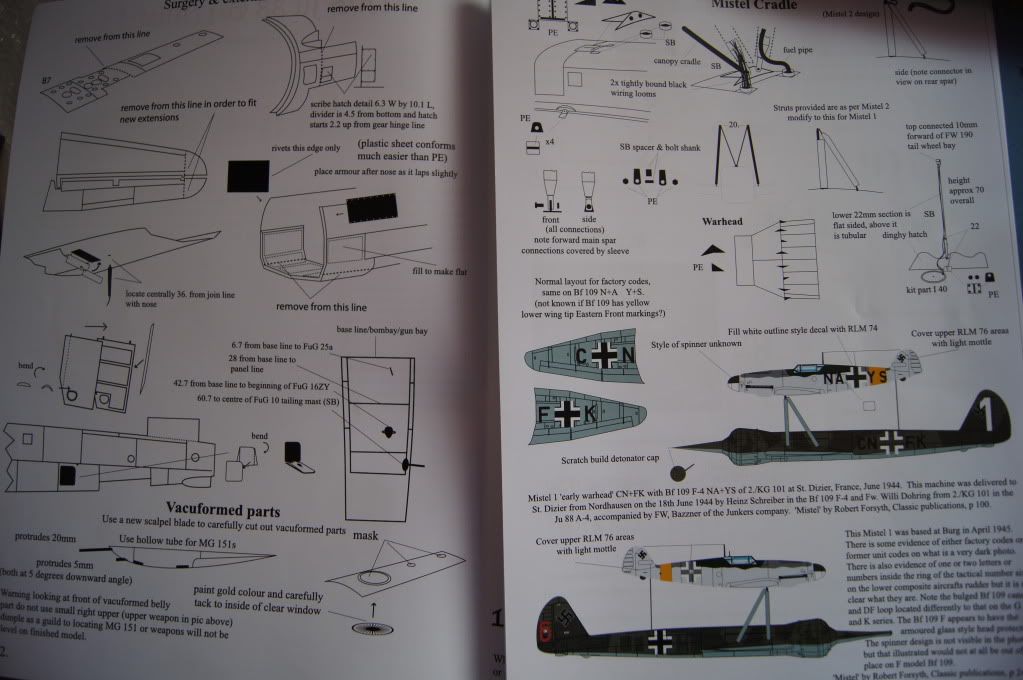

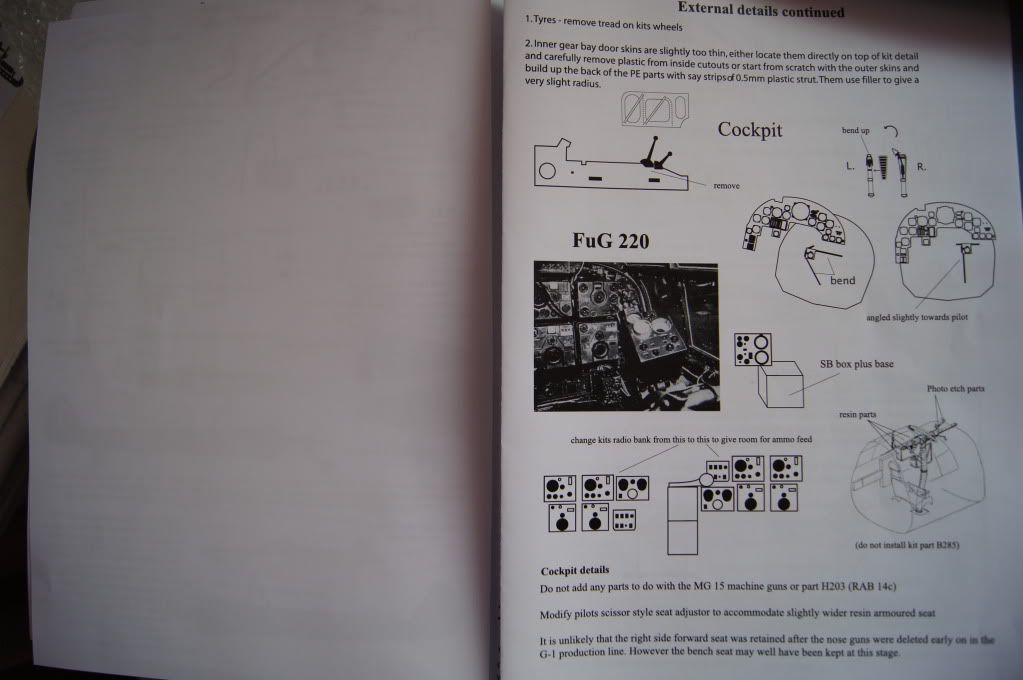

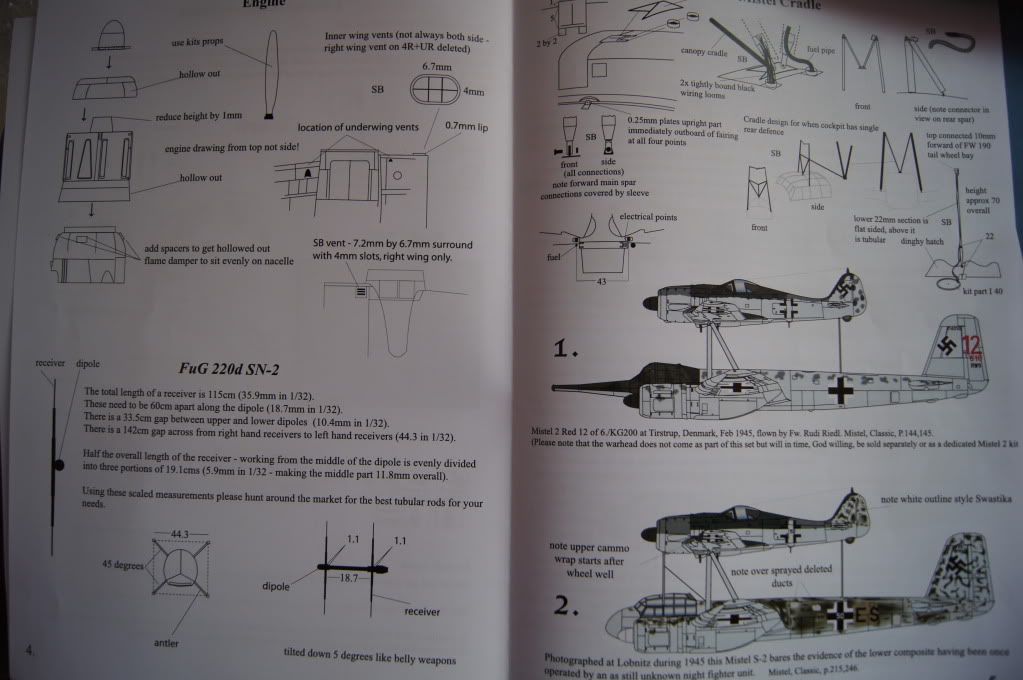

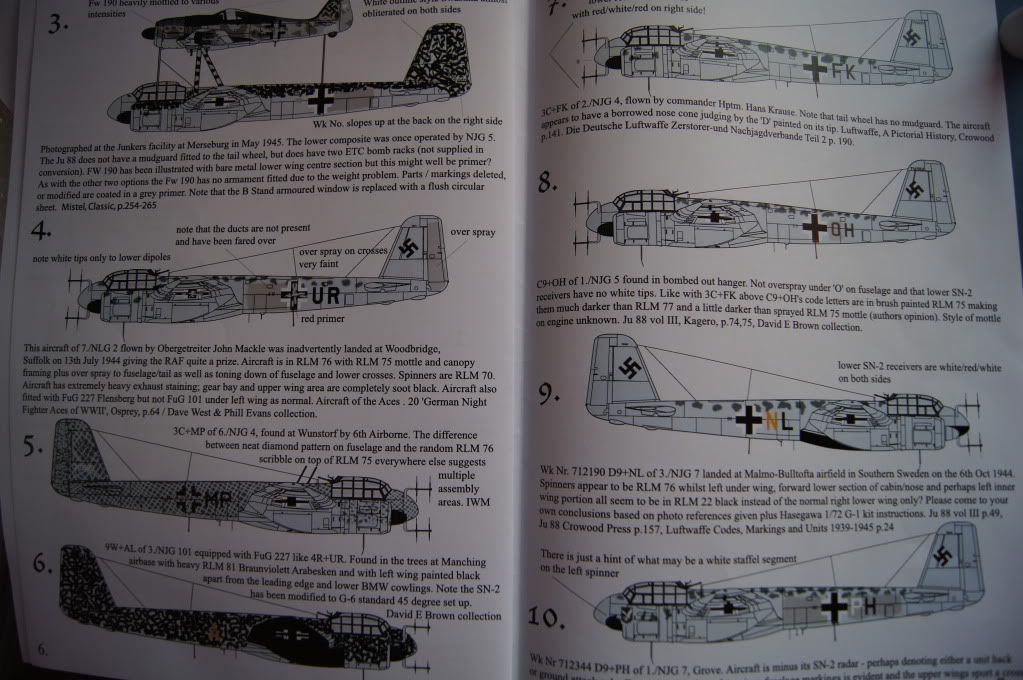

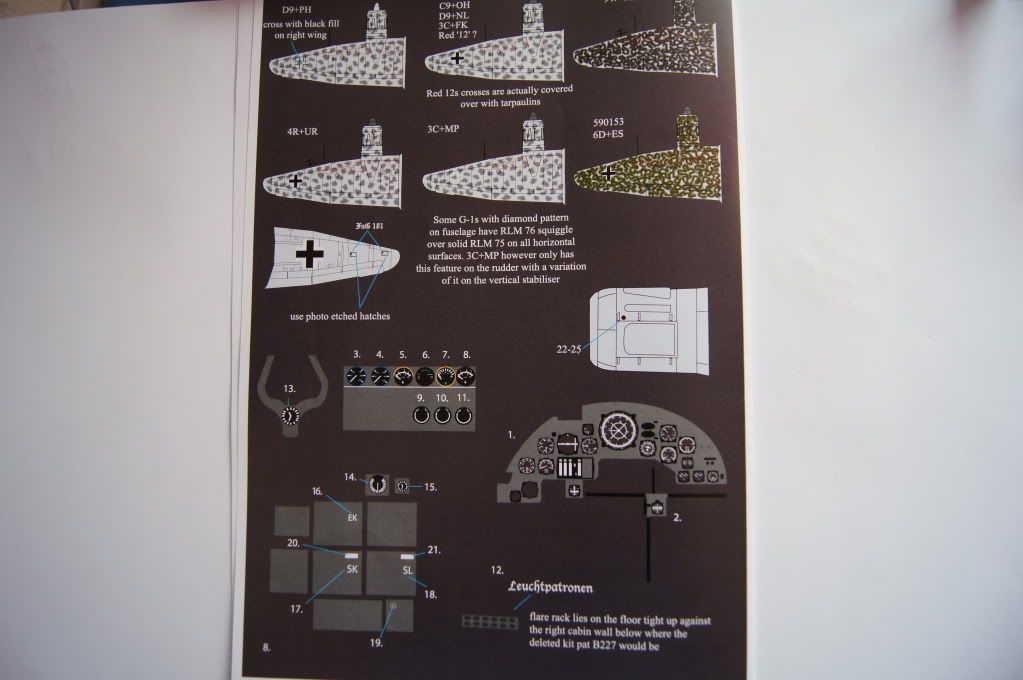

Instruction sheet is a bit vague but i will soon figure it out.

Mistel history

The first double powered aircraft composite, was actually built and designed by the british. In this brief intro to the history of composite aircraft, there has been many other examples of this concept but i'm not going to focus on them mainly because they were all either, Zeppelins or Airships that carried a single engined fighter.

On 16 May 1916, an intriguing contraption comprising a flying boat carrier aircraft witha Bristol scout C fighter mounted on it's upper wing, effectively the first known two-aeroplane composite arrangement. This slid down the slipway at the RNAS station at Felixstone on the east coast of England. This being the beginning of an innovative experiment to improve furthur on the strike response time of carrier-borne intercepts. The designer of this concept was a 33 year old Irish-born squadron commander John Porte, the commander of the Felixstone station.

In late 1915, Porte had commenced work on the prototype of a large three-engined flying boat of his own design, the Porte baby. Between 1917-1918 the Porte baby saw operational service with the RNAS stations at Felixstone and Killingholme but they proved to be vulnerable due to their low speed and lack of maneuvrability.

Porte's method was to mount the scout biplane in a cental position on the Porte baby's upper wing. The scout's fixed undercarriage was positioned immediately in front of the leading edge of the flying-boat's wing, the wheels resting in special crutches carried on struts from the engine bearers of the Baby's central engine. The scout's tail-skid was secured by a quick release toggle controlled by the fighter's pilot.

At 10:50 am on 17 May 1916, in fine weather and over a moderate sea, the baby took to the air. The scout played no active part in the take-off and it's engine remained switched off throughout. Once the combination had reached a height of 1000ft over Harwich, the pilot of the scout, Flight Lieutnant M.J. Day, switched on his engine, ran it to full power and, according to one commentator, lifted away from the flying boat "Like a dove from a roof". This was the first and only successful flight of this composite.

During post war Britain aircraft designers experimented with the concept. In 1928 however, Norman Macmillan, test pilot at the Fairey aircraft company, obtained a patent for "aircraft coupled in paires or trains". Macmillan envisaged a method whereby an aircraft carried above itself a "gliding bomb", loaded with either ammunition, stores or mail and which, if necessary, could also "be used for attack". This was only adopted as a means to launch target gliders for anti-aircraft gunnery practice by the Royal Navy.

The notion was rested until April 1932 when another patent was granted to Major Robert Hobart Mayo, a former Martlesham test pilot and then the general manager (Technical) of the British airline, Imperial Airways, for "aircraft carrying other aircraft". The origins of Mayo's application lay in response to the problem of the carriage of air mail between Britain and North America.

There were three potential solutions to the endurance problem, of which two were impractable. The third and perhaps most radical solution lay in Major Mayo's proposal. Mayo called for a heavily laden mailplane to be fitted on top of a larger more lightly loaded carrier aircraft, which would then transport the mailplane to it'ss operational altitude at which point the component's would seperate. The mailplane would then continue to it's destination burning enough fuel en route to be below it's maximum permitted weight for landing. The lower aircraft or 'component' would then return to it's base.

In 1935, a contract for the construction of a single Mayo composite was awarded to Short Brothers. The lower component was designated the S.21, registered G-ADHK and named Maia. The upper component was designated S.20 registered G-ADHJ and named Mercury.

When coupled, the two components of the Mayo composite effectively functioned as one aircraft, the controls of the upper machine being locked and it's pilot only contributing to thrust and lift.

Mayo's original intention had been to allow seperation of the two components by means of the upper component's elevator control, but this was discarded as too risky. Later design centred around using the differential lift-coefficients of aerofoils for the two components arranged in such a way that, as speed increased, the upper component took a greater share of the total lift than the lower, thus creating a positive seperating force strong enough to overcome spring detents intended to hold the components together.

For the remainder of 1937, both components continued to be flown separately whilst stability and positioning tests were made. On 1st January 1938 taxing trials began with the complete composite assembly. During one such trial the composite accidentally became airborne for a short time whilst the Shorts designer and project manager, was observing the release gear whilst still standing on top of the lower component. They were left to grasp firmly onto the support pylon.

Having completed many records, during which the composite set a new world seaplane distance record and two susequent mail trial's to Eygypt, Maia was destroyed during a German night raid on Poole harbour on 11 May 1941.

On 18 July 1927, Hugo Junkers (owner of the Junkers company, later to be renouned for the JU88, JU87), lodged an application in Germany for an invention in which, "a flying machine is placed on or connected with another flying machine of some suitable type, which serves for imparting to the machine to be started an additional acceleration and, if desired, to support it in th air until a predetermined altitude has been attained". Junkers intended that "any desired type" of aircraft could be used for both components of the Huckepack composite arrangement.

Junkers foresaw that such a principle could be adapted for both land and water take-off's and landing's. Junkers death eight years later was probably due to the increasing pressure placed upon him by the ambitious and combative Staatsekretar, (State secretary) of the Reichsluftfahrtministerium, (RLM or Reich Air Ministry), Generalmajor Erhard Milch. Milch had victimised Junkers following the old man's resistance to his demanding aircraft production programmes, which included placing all the Junkers patents and factories at the disposal of the Reich. The pressure proved too much and Professor Hugo Junkers finally yielded, selling the controlling interests in his company in October 1934 and resigning his directorships the following month. Hugo Junkers died at his home in Bavaria on 3 Feb 1935.

To date no furthur information of any other proposal has come to light and with it, it seems initial German research into composite aircraft ended for several years. At least one source suggests that the origins of what would become the Luftwaffe's future composite concept, 'the mistel', may have lain in pre-war discussions between Major Robert Mayo, the British designer of the Short-Mayo composite and Milch. Milch visited England in October 1937 as head of a hight-ranking Luftwaffe delegation which toured airfield's and aircraft factories in the midlands on a "goodwill" mission. It is believed that Milch also met Major Mayo at this time who was keen to promote his design, if not a little frustrated at apparent British inertia over it.

In any event, the declaration of war in 1939 brought an end to all these purely peaceful projects and experiments, both British and German.

By October 1942, Adolf Hitler was faced with dangerous and draining military predicament, both on the eastern front and in Africa.

Far away from the battlefront, in the relative peace and safety of the South German town of Ainring nestling in the foothills of the Alps, creative minds were at work. The DFS (Deutsche Forschungsanstact Fur Segelflug - German research institute for gliders) was formed in 1925. This was later transferred to Darmstadt-Griesheim in 1933, and another move to Ainring airfield located 7km west of Salzburg.

It was here, as the crisis at Stalingrad grew and the military situation in North Africa deteriorated, that Fritz Stamer proposed a radical sceme for delivering troop-carrying gliders. Instead of a glider being towed behind a powered aircraft, Stamer's idea was to mount it rigidly beneath one and then to jettison it over the target area. The first Mistel experiements took place in Octobe 1942 and were made witha Klemm Ki 35 lightplane mounted above a DFS 230 B-2 glider.

In 1937, Reitsch helped to prove the concept, when she separated from a ju52, put the DFS 230 into a dive and made a perfect landing directly in front of a group of Luftwaffe dignitaries including Milch, Kesselring, Udet and Von Greim who watched eight fully armed troops charge out of the glider and adopt assault position.

Two subsequent high profile glider operations involved the DFS 230 supported this view. The first being the successful capture of the Belgian fort of Eben-Emael. The second major occasion was during the successful but hard won German airborne assault on Crete a year later.

The 1942 experiments at Ainring however, repesented the first stage in developing the Mistel combination. It was also intended that the operational range of the combination should be increased so that the glider could carry as a minimum, sufficient fuel for the Mistel combination to fly it's mission and then, following seperation, for the upper component to be able to return with full tanks.

On 21 June 1943 a new combination comprising a DFS 230 carrying a Messerschmitt BF109E fighter was ready for flight testing. By this time of the war the E varient of the BF109 had largely been phased out of service, for the favour of the up-rated BF109F and G series. This combination was able to take off without assistance, climb, separate in the air or land still attached. There were many modifications to the design (mainly due to the increase in weight of the new bf109E, and near collosions when both aircraft commenced the seperation procedure). These tests revealed the need to fit a dive brake to the truss framework.

A furthur series of tests was then conducted to test the effects of extending the dive brakes and to check that it produced the desired pitching moment. The sink speed was found to increase substantially and a nose down pitching moment was produced. A lattice-type dive brake was mounted and hinged at right angles to the direction of flight and with a large gap between it's lower edge and the upper surface of the wing of the DFS 230.

As a result of the Ainring experiments, Germany now had the theoretical and practical proof, that the principle of the composite aircraft was not to be ignored or dismissed. There were those who had already recognised the significant military potential of the Mistel as an offensive weapon. The question now was how best and how quickly the weapon could be developed and exploited.

The man perhaps most recognised as being the originator and driving force behind the Mistel concept by the Luftwaffe was, Flugkapitan Siegfried Holzbaur. In 1939 as war broke out, Holzbaur formulated the idea for the developing a so-called Grossbombe or ' Large bomb', principle whereby an enormous bomb would be delivered to a target, such as a ship, by a smaller aircraft mounted on top of the bomb's upper surface, or even partially embedded into it.

At the end of December 1941 and on the strength of his unofficial experiments, Holzbaur prepared a report for the Junkers project office, in which he proposed mounting a small aircraft above a larger, explosive-filled aircraft, which would be used to control, aim and release the latter at a target. Holzbaur proposed using waery BF109's for the upper, and JU88 bombers for the lower aircraft, whose airframes and engines had reached their maximum permissible service hours and were thus expendable. He also proposed replacing the autopilot with a thre-axis control system and a gyro-stabilised sight.

Much to Holzbaur's disappointment however, the RLM apparently failed to understand the opportunities presented to them and Goring showed only limited interest in the project. Nevertheless, Goring did go as far as to authorise further tests to be conducted at Dessau and in early 1942, the ju88 V21 was fitted with a modified patin PDS, (Patin - Dreirudersteuerung) three-axis control system and a gyro-stabilised sight with which target aquisition flights were made. The flight paths being measured with a theodolite fitted with a cine-camera. The aircraft was tracked up to a point close to the target and the subsequent flight path was extrapolated from the measurements. Repeated experiments conducted by Junkers using this system showed that a target measuring 15m X 15m could be hit with guaranteed certainty.

The results from these experiments were forwarded to Goring and the RLM, but no response was forthcoming. Furthermore, commitments to other contracts then being fulfilled by Junkers did not allow the company enough time to pursue the matter further, and the project was shelved.

On 17 July 1943, the DFS institute drafted a report for the RLM in which it outlined it's perception of how the combination could be used in an offensive military capacity: "The JU88A-4/BF109F Mistel combination offers the possibility of using the JU88A-4 as an unmanned Grossbombe remotely controlled by the BF109F to a target on a pre-determined glide path. With a range of 1,500km, the Mistel can still deliver a 3.5 ton payload of high explosive. Such target aircraft can be stripped of all unecessary equipment and can threfore carry substantial amounts of explosives". The 'unnecessary' equipment was classified as the dive brakes hydraulics, automatic dive mechanism, defensive armament, radio and bomb aiming equipment. The maximum take-off weight being 16,000kg.

Junkers installed the PDS flight control system and the DUZ company transferred the throttle controls from the JU88 to the BF109. The composite was constructed in such a way that the BF109 rested on two three legged support structures and was fastened with spherically-aligned bolts. The structures were attached to points on the front and rear spar joints as well as to frame 9 on th JU88's fuselage. The third attachment was made in front of the tailwheel of the BF109 via a collapsible strut, which enabled the BF109's incidence to be increased during seperation. The collapsible strut was attached to frame 20 of the JU88's fuselage. The BF109 was fastened to the support structures by means of explosive bolts. On seperation, only the bolt keeping the collapsible strut straight was detonated by the pilot. The subsequent increase in the angle of incidence of the BF109 operated a switch to command the detonation of all three bolts holding the aircraft.

The JU88's engines were throttled mechanically from the BF109 via the linkage supplied by DUZ, which during the release sequence was also explosively seperated. The throttle levers fitted to the BF109 were much longer than those normally found in the JU88, in order to overcome the highter friction forces associated with the modified throttle system. Two dual-function instruments, indicating engine manifold and engine speed (RPM), were fitted to the BF109 to moniter the performance of the JU88 engines.

The PDS system enabled the Mistel combination to fly solely under control from the BF109. The system could be operated in two conditions, 'automatic' and 'cruise'. In cruising flight, control movements were measured by potentiometer and transmitted electrically to the servos coupled to the flying control surfaces of the JU88. In 'automatic', flight condition, the JU88 could be controlled by switches fitted to the BF109's control column and instrument panel. The switches were arranged to send directional and lateral control commands to the JU88, in the same way as if the pilot were physically controlling the aircraft. While part of the Mistel combination, the BF109 took it's fuel from the outer starboard (right) wing tank of the JU88.

By November 1943, despite proven co-operation between Junkers and the DFS, development work on the Mistel was causing some tensions in the corridors of power at the RLM in Berlin. They grumbled that, "the chance of success was questonable and, based on past experience, the work force would be better employed on other tasks". Nevertheless, this is one of the first signs that the RLM was beginning, albeit begrudgingly to accept the Mistel concept as a feasible military possibility.

For the warhead of the composite, the German designers turned to thr hollow-charge principle. This was no means a new or unique form of armament, since ground use hollow charge weapons were used against tanks. What was unique about the fitting of a hollow charge warhead to the Mistel however, was the sheer size of charge involved. The specialists at the RLM, were presented with the unique chance of creating an explosive charge without having to take into account it's ballistic shape and size. This warhead was, in effect, and oversized Panzerfaust, which was capable of penetrating armour plating 120cm thick. Tests of the warhead revealled temperatures of 3,000 - 4,000 degrees centigrade, with the speed of penetration measured at 11,000 M per second.

The 1700kg of explosive and detonator for the main charge was placed at the rear of the warhead with a conical cavity to the front of it, 1.8m in diameter. The cone was lined with a layer of soft metal, either aluminium or copper, with four electrical crush fuses positioned at the tip of a 2.75m probe, protrouding from the front of the warhead and known as the Elefantenrussel, ('Elephant's Trunk'). Soft metal was important, since a harder metal would prevent the hollow charge functioning properly. When this probe struck the target, the fuses would trigger the detonator behind the explosive charge. The detonator circuit was not closed until the upper aircraft had seperated and after some 2-3 seconds had elapsed. In addition, the warhead could not be armed until the carrier aircraft's landing flaps had been retracted. This safeguard prevented the warhead from exploding in the event that the upper aircraft was deliberately or unintntionally seperated during an aborted take-off. After firing, the charge, a mixture of 70% Hexogen high explosive and 30% Trinitrotoluol, would focus all it's force on the soft metal liner which would then liquefy and project forward in a fine jet. This jet could drill a hole through more than 8m of armoured steel or 20m of reinforced concrete.

The length of the probe could be varied to trigger the charge at the optimum distance from the target. The entire detonation procedure took place within 1/10,000th of a second.

It was intended that a warhead with similar capability could be fitted to a purpose - converted JU88 with relative ease. To facilitate this, a JU88 would have it's crew compartment removd at the aft bulkhead, this process being carried out at a Junkers Mistel conversion facilty. Four spherically alligned quick release bolts were fitted which allowed the crew compartment to be re-installed for training purposes or ferrying to an operational airfield.

Then, once delivered to an operational unit and at the time a mission was ordered, the crew compartment would once again be removed and the warhead fitted, again using the quick release bolts. This process lasting approximately one day, required a team of six mechanics, two armourers and a crane, capable of lifting four tons.

After the warhead was attached the composite had to b towed to the take-off position, because the pilot of the fighter could not operate the brakes of the JU88. The fully laiden weight of the operational Mistel was about 20,000kg, some 7,000kg heavier than a normally loaded JU88. This placed heavy demands on the undrcarriage which really needed to be completely redesigned. In fact, no such modifications were carried out, and the undercarriage was extremely prone to collapse on take-off.

Towards the end of 1943, one of the first Mistel's to be assembled at Nordhawsen was transferred to the Erprobungsstelle der Luftwaffe at Peenemunde-west on the Baltic coast. It was here in February 1944, the first airborne trial of a Mistel with a 'live' warhead to be tested in flight. The composite was airborne following a faultless take-off, under the watchful gaze of high ranking officals from the Luftwaffe and RLM. The target was to be the Mons-Klint, a 110m high chalk cliff on the Danish island of Mon, 120km to the North-West of Peenemunde. During the flight, suddenly , the composite lurched in the air and the JU88 felt as it was pulling towards the earth. Holzbaur wrestled eith the controls and tried to throttle back the engines in a attempt to correct his course, but the machine refused to respond. Locked together, the two aircraft began to dive towards a little coastal village of Thiessow. Holzbaur had no other alternative but to seperate his aircraft. The BF109 bucked in the air and climbed away as the explosive-laden JU88 plummeted and smashed into the ground, just 3km from the village .

There was a momentary burst of flame, a tremendous explosion and a moment later, a mushroom shaped cloud of smoke rose 900m into the air. Nothing remained of the JU88 and a search around the enormous crater proved fruitless. Later Holzbaur, who was a well-built man, believed the only possible explanation for the Mistel failure, was that in the narrow confines of the BF109's cockpit, he had inadvertently cut out the main guiding mechanism causing the JU88 to fall out of control.

Junkers, by this time now officially referred to the Mistel as 'Beethoven-Geat' : Ausgesteuertes Unbemanntes Flugzeug Fur Totaleinsatz, ('Beethoven-equipment' : Automatically controlled, unmanned aircraft for Totaleinsatz). The word 'Totaleinsatz' signified the intention to use this weapon in the knowledge that it would be expendable.

For the planners of the Luftwaffenfuhrungsstab, the time had come when the Lutwaffe urgently needed to, 'deliver something spectacular', something that could prove to Hitler and the Geramn people, that their air force was still capable of hurting it's enemies where they least expected it. As one option, they turned to the still untried Mistel.

Three main targets were considered which offered, the most promising chance of success. The British naval base at Gibraltar, the British home fleet anchorage at Scapa Flow in the Orkney islands to the North of Scotland and the Russian fleet at Leningrad.

By April 1944, production of the initial batch of 15 Mistels was underway. The OKL now faced the dilemma of whether to deploy only some of them against this target and the remainder against Leningrad or another target, or whether to make two attacks against the Royal Navy anchorage. Certain considerations influenced the Fuhrungsstab in their eventual decision. Firstly, Scapa Flow lay some 700km West of the Luftwaffe airfield at Grove in Denmark. From here, a Mistel could reach the target provided that the BF109 was fitted with a 300 litre auxiliary fuel tank. Secondly, it was known that a number of the Royal Navy's largest warship's including aircraft carriers and battleships, regularly passed through Scapa Flow whilst assigned to the Home Fleet. On 16 April 1944, Oberst I.G Eckhard Christian signalled the Fuhrungsstab's intentions when he wrote: "Make preparations for an attack on Scapa Flow". However, though certain logistical efforts were made to put the planned operation into action, a Scapa Flow attack force was not assembled until February 1945. The allied invasion of France was to demand a more immediate role for the first operational Mistel.

As early as February 1944, the month that Holzbaur conducted his first test with a 'live' Mistel against the Mons-Klint in Denmark, the Luftwaffe took steps to establish it's first operational Mistel unit. The small Harz town of Nordhausen would gain considerable post-war infamy as the site of the notorious underground aircraft and rocket factory known as the Mittlewerk located beneath the anhydrite hills at Niedersachswerfen just North of the town. By mid 1944, more than 8,000 slave labourers were toiling in the fetid, ammonia dust filled air of the factory's tunnels. Nordhausen airfield, however, was located to the South of the town ans served as a normal military facility. Once the JU88's began arriving at the airfield for refurbishment and Mistel assembly by the Baustelle Schwab/Nordhausen towards the end of 1943, Siegfried Holzbaur established a Junkers co-ordination office close to the railway station. Under the supervision of Holzbaur and his small detachment began training, Rudat recalled, "Instruction on Messerchmitt's fighter was brief. A few days later, i made my first flight with the Mistel. I have to admit thet i did not feel very confident sitting high above the ground in a BF109 mounted to a JU88. Take-off proved to be a problem; control commands electrically transmitted from the upper to the lower aircraft seemed to take rather a long time reaching the JU88's control surfaces before they responded to the command. The pilot, therefore, had to anticipate every manoeuvre before it actually took place. During training with the Mistel S-1, the JU88 was also flown with a two-man crew, who were able to correct any bad mistakes made by the pilot of the 109".

"Everything turned out well and after take-off, i was surprised to find how easy it was to control a large composite aircraft from a small fighter cockpit. I was particularly impressed by the accuracy of the three-axis, gyro-stabilised autopilot. During mock attacks, very little control movement was needed to keep the composite on course towards it's target, once the aircraft had reached it's final speed. During this period, around 35 men, (mainly crew and technicians) relocated to Nordhausen, where they too would receive technical training on the composite. Both pilot and technical training continued throughout May, but the following month, events suddenly, but not unexpectedly, overtook the Germans.

On 6 June 1944, undr the code name Operation Overlord, the Allies landed on the coast of Normandy. An armada of some 6,500 naval and transport ships crossed the English Channel supported by 12,000 aircraft. Among the various units ordered to move into France to engage the invasion forces was 2./KG 101 (Mistel unit), which was assigned to attack large Allied ships off the Normandy coast. By 10 June, the unit's ground and signals personnel had arrived by rail and established themselves on an airfield near St. Dizier, 190km East of Paris and 90km South of Reims. However, preperations to fly in the Mistel had begun at Junkers Nordhausen works several days earlier under the co-ordination of Siegfried Holzbaur.

Early on the morning of 14 June 1944, a Mistel S-1 comprising a BF109 (DM+UC) and the JU88 V9 (CH+FI) took-off from the Nordhausen works en route for France. The JU88 was flown by Fw. Emil Degering of 2./KG 101 with Heinz Schreiber in the co-pilots seat. Fw. Bazner occupied the BF109. The Mistel touched down safely at St. Dizier shortly before 10:00 hrs. As Schreiber was not required to give any local training, but merely act as a ferry pilot, he and Degering flew back to Nordhausen that afternoon to fly in the next composite. Yet it was to be only hours before the Luftwaffe would lose it's first Mistel to enemy action.

Meanwhile, 221 lancasters and 13 mosquitos carried out RAF Bomber Command's first daylight raid since May 1943, when they attacked the German Navy's fast motor-torpedo boat base at Le Havre. Now, with it's naval capability severely weakened, the Germans needed more than ever, a weapon with which to strike at the massive armada off the coast and on the night of 14 June 1944, the Mistel underwent it's baptism of fire.

On the 14 June, the weather was good, with a few broken clouds, at 23:20 hrs, at 11,000ft over the beachhead area, Flight Lieutenant Walter 'Dinny' Dinsdale, and Flying Officer John Dunn, crew of a night fighter Mosquito MK X111 (HK476), was able to see his target quite clealy. It was moving slowly, so slowly that Dinsdale was forced to lower his wheels and flaps in order to avoid ovrshooting. He closed in from behind and below. John Dunn continues:

"Mobile GCI was advised of contact and visual and 'chatter' with GCI was cut off while we assumed contact. We then closed to 1,000 ft astern of the Bandit, checked IFF, no resins, no battle stripes. We closed to 750 ft and made positive identification with th aid of Ross night glasses on a JU88 with what appeared to be a glider bomb attached to the upper fuselage. Strangely enough, there was no evasive action taken by the Bandit throughout this action. At 750 ft, my pilot opened fire with a short burst from our four 20mm cannon, parts of the enemy aircraft burst into flames and it banked to port and went down ina step dive. We followed on AI and visually. It hit the ground South East of Caen at 2:40 hrs. There was a massive explosion which lit up the whole countryside. Hedges, roads and buildings were visible".

However, what Dinsdale and Dunn had actually shot down was one of KG 101's first Mistel probably making a training and familiarisation flight close to it's intended zone of operations; it was thus the first Mistel ever to fall to enemy action. It had taken a total of 15 rounds of 20mm semi-armour piercing incendiary rounds and 17 high explosive incendiary rounds from Dinsdale's guns to despatch the composite. The Mistel was probably an S1, BF109, W.Nr 10130 (CD+LX) and JU88A-4 W.Nr 10096 (5T+CK) 'White 5', which crashed 40km South East of Caen.

However, though new aircraft were arriving, ground support equipment was lacking and, without a heavy crane to mount and install warheads, the ground crews and technitians were forced to commandeer a large excavator for the purpose. Attempts to begin operations in earnest began on the evening of 24 June when it seems five of the twelve available Mistel were prepeared for an attack against an Allied convoy in the Bay of the Seine in which was reported to be the battleship, HMS Nelson.

Fighter escort for the Mistel was to be provided by BF109's of 1./JG 301. Additionally, a small formation of JU88's 'pathfinders' from 1./KG 66 were to drop LC50 illumination flars ahead of the composites. They took off at 22:18 hrs following a course which took them West, directly over Rouen towards the Bay of the Seine.

At St. Dizier, with warheads fitted comprising 70% Hexogen high explosive and 30% Trinitroluol, Oblt. Rudat prepared his aircraft for take-off. The entire Mistel operation was cloaked in secrecy, German anti-aircraft batteries along the route were only informed of the operation at the very last minute and were ordered not to fire One of the batteries had not been informed in time and when at a height of 1,500 metres, the Mistels came under fire.

Oblt. Rudat recalles (Flying whit 1, the Mistel i built):

"My left engine was hit and stopped. Even today, many years later, i remember the feeling of sitting on top of an enormous warhead and being shot at by our own flak. I still don't like the feeling. Because i was unable to feather the propeller of the 'dead' engine, i lost speed repidly and was unable to keep up with the other three Mistel of my Schwarm. The warhead was specially designed to destroy heavily-armoured targets. Ours, therefore, were to be battleships or cruisers in the Bay of the Seine covering the invasion fleet, though any ship was an acceptable alternative".

"In the meantime it had grown dark. West of Le Havre, i notied a British night fighter and i became concious of the fact that i had no means of defending myself, my guns had been removed. Because my JU88 tended to want to turn continually to the left, i decided to make a direct attack on the numerous landing craft saturating the coastline. Something would definitely be destroyed, even though i could not claim success. After aiming the JU88, i seperated and immediately turned inland to escape the night fighter. The JU88 turned over on it's back and dived straight into the sea, causing a terrific explosion".

Elswhere, another Mistel pilot, Fw. Saaifeld, experienced control difficulties and was forced to conduct an emergency seperation. His JU88 also crashed into the sea. Another Mistel, which was apparently succussfully launched at the enemy ships from a height of 245m, hit the sea and exploded close to HMS Nith, a 1,370 ton River Class frigate lyin at anchor off Gold Beach. The JU88 was so close that it's wing cut a lifeboat in half. Despite the severe damage inflicted upon HMS Nit, it was a relatively disappointing and unsatisfactory debut for the Mistel. Rudat and Saalfeld had been forced to jettison and the remaining pilots appear to have launched their aircraft without sufficient accuracy. Another Mistel is reported to have crashed on take-off at St. Dizier and one, possibly two pilots were missing.

Throughout July 1944, the allies were picking up more and more evidence of German composite activity. On 4 and 7 July, Mistel were seen by Allied reconnaissance aircraft at KG 101's Kolberg training base. ON 18 July 2./KG 101 recieved orders to carry out the last ant-shipping attacks, before the Korps withdrew into Holland. The target was a French battleship anchored off the Orne Estuary. Escorted by fighters from 1./JG 301 and with with flare-droppin aircraft flying ahead, an unknown number of Mistel took off from St. Dizie. The raid was apparently unsuccessful and to some extent, the Luftwaffe appears to have been duped.

On the night of 10/11 August, KG 101 launched another attack against shipping in the Bay of Seine from St. Dizier. Once again 1./JG 301 was ordered to provide escort. During the attack, one KG 101's pilots became disorientated and somehow drew near to the South coast of England. With fuel running low, the pilots decided to jettison his JU88 A-4 lower component and attempt to return to France. Once seperated the JU88 flew on, crossed the English coast, and eventually crashed into open countryside at 23:35 hrs, at Slade Bottom Farm in the village of Binley near Andover, Hampshire. The force of the blast reportedly blew a man over some three miles away.

By 24 August, most of the newly redesignated Einsatzgruppe/KG 101 was now established at Rhein-Main, though the unit continued to carry out some training at Kolberg.

On 13 September 1944, Luftflotte 3 ordered 'all available' Mistel into action for an operation over the Albert Canal that evening. The target was to be a point near Beeringen, where armour from the British XXX Corps was crossing the Canal to threaten elements of Kampfgruppe Chill, a force assembled by Generalleutnant Kurt Chill. As for some unknown reason, Einsatzgruppe 101 did not deploy on this occasion and the British pushed on with their advance.

What was effectively to be the swansong of Mistel operations on the Western Front occurred just under two weeks later when Einsatzgruppe 101 was ordered to make an attack on the Nijmegen Bridges. On the night of 27 September, four Mistel took off from Rhein-Main together with eight JU88 S bombers which had been seconded to Einsatzgruppe 101. One Mistel and two JU88's were forced to break off their attack and another Mistel went missing. The two remaining composites reportedly launched at the bridge, but missed the target.

In late september 1944, the component, Einsatzgruppe/KG 101 were redesignated into III./KG 66. According to surviving records, the unit's first attempt at operations took place on 3 October when Five Mistel 1s of 8./KG 66 under the command of Oberleutnant Karl Horst Polster flying in a BF109 F-4 upper component (W.Nr 140572), took off from Burg in poor weather conditions to attack the Nijmegen bridge at dusk. However, disaster struck on their way to the target when, due to the adverse weather, three of the Mistel crashed into the Teutoburger Wald, a large tract of hilly forest stretching between Rheine and Bielefeld. Oblt. Polster, Uffz. Fritz Scheffler, flying a lone BF109 F-4, and Uffz. Paul Baranski were killed. The remaining two composites were unable to find the target and their pilots were apparently forced to jettison their JU88 lower components. Fw. Franz Heckmann, was shot down by fighters in his BF109 F-4 (W.Nr. 12896), over southern Holland.

By late 1944 significant numbers of the FW190 A-6 and A-8 figter and F-8 ground attack varients were available, which in itself forced further development and new design. Dr Fritz Haber, head of development. construction and flight trials for the Mistel project at Junkers, offers plans to the introduction of the FW190 as an upper component. On 5 December 1944, Heinz Schreiber piloted an FW190 (SR+GG) fitted to a JU88 G-1 (PI+XU), for a 25 minute flight around Nordhausen. Things went relatively well and instructions were issued to the Junkers factory at Leipzig-Mockau to adapt 75 JU88G-1 night fighters for the Beethoven programme.

On 21 December 1944, it was reported that 12 JU88/FW190 combinations had been completed, with another 20 due by 15 January 1945 and a further 30 by 15 February. However, such was the entusiasm for the Mistel by this stage, that the order was extended to 100 units capable of attaining a range of 1,500km to be available by 1st February, and a further 100 capable of 2,500km to be ready by 15 February at the latest.

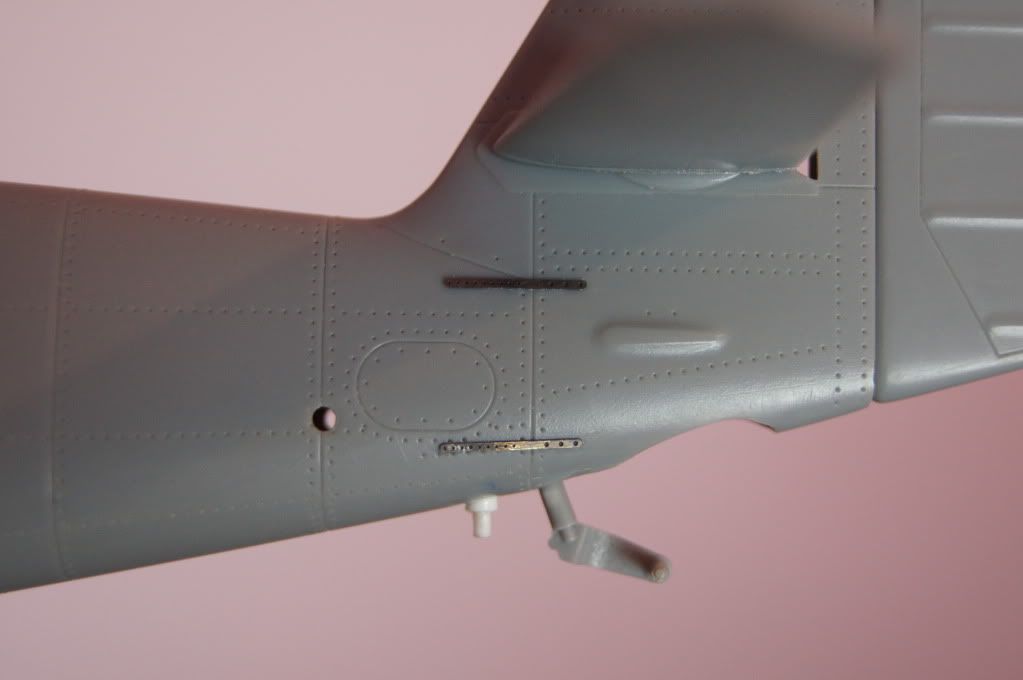

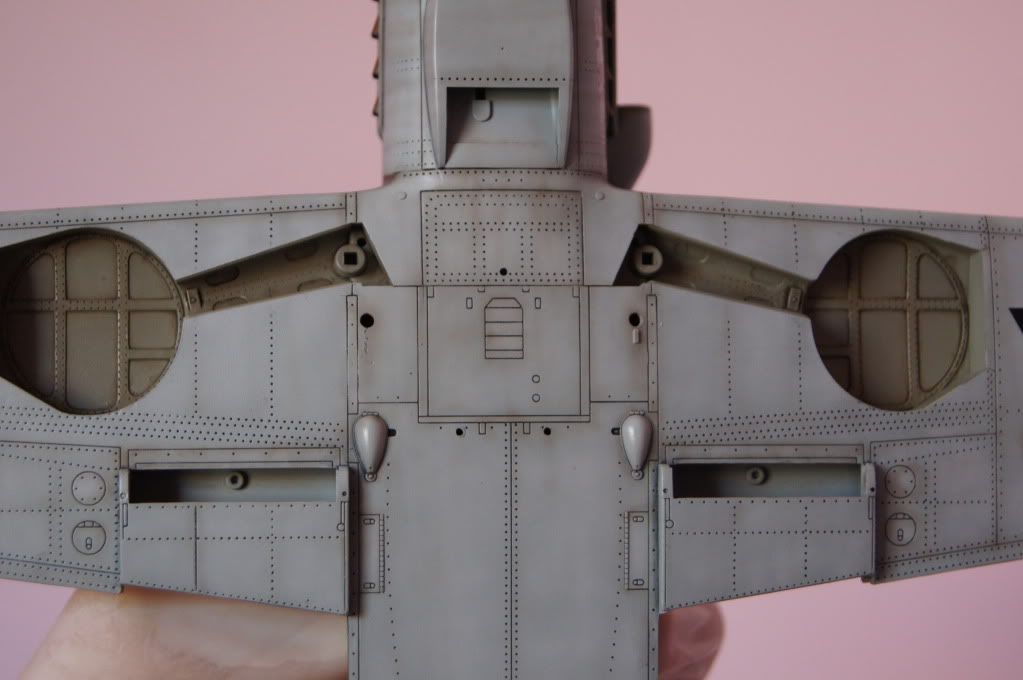

Ok these are some progress pics i have so far

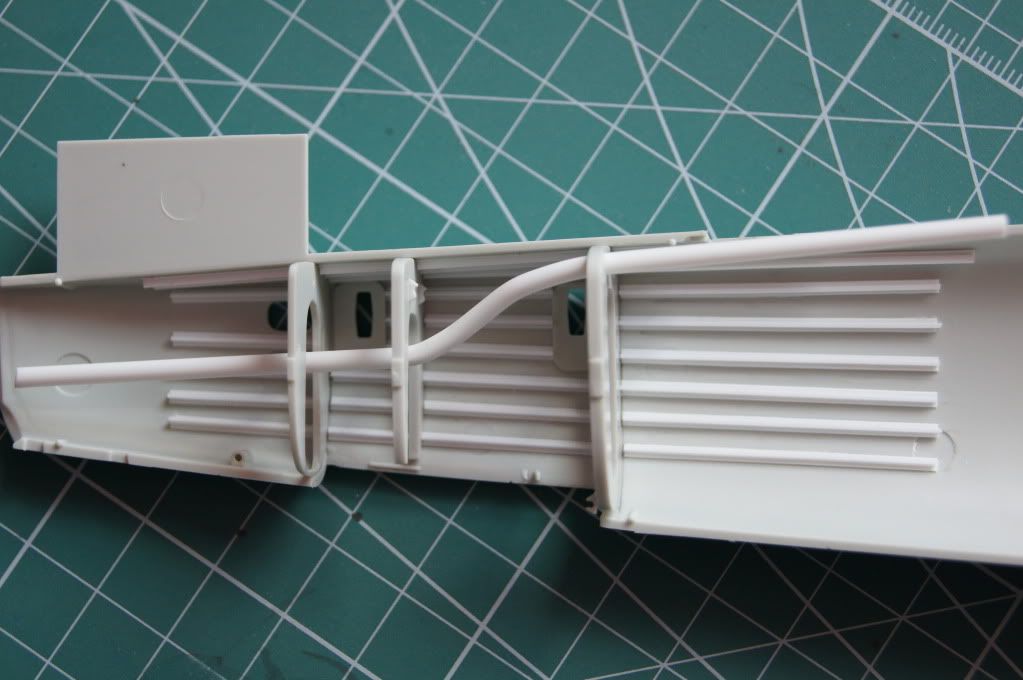

I made the ribs by first cutting some thin plastic card, (not sure on the thickness), and cut them into strips of 1.5mm thick, (10 lengths at 15cm long in total). I glued these using tamiya extra thin at around 2-2.5mm apart. Then glued some evergreen strip styrene, (0.56mm X 0.84mm), on top of the others to resemble an upsidedown T.

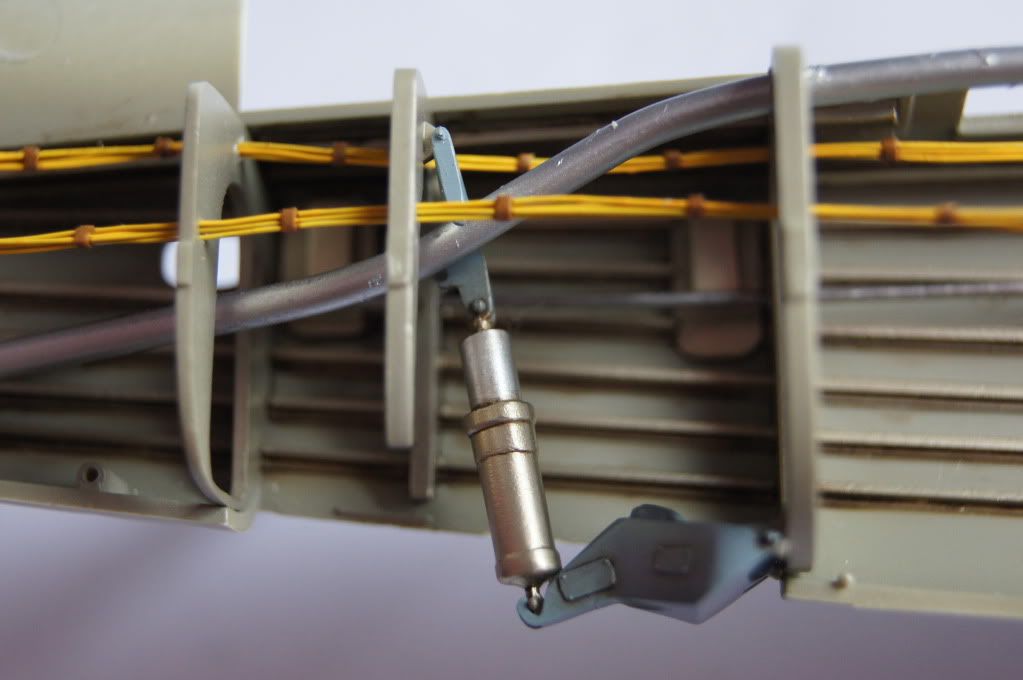

The pipe is evergreen plastic rod, (3/32" or .093Diameter or 2.4mm), to resemble the fuel dump pipe. A lot more wireing plus the rear landing gear will be placed in to make it more busy.

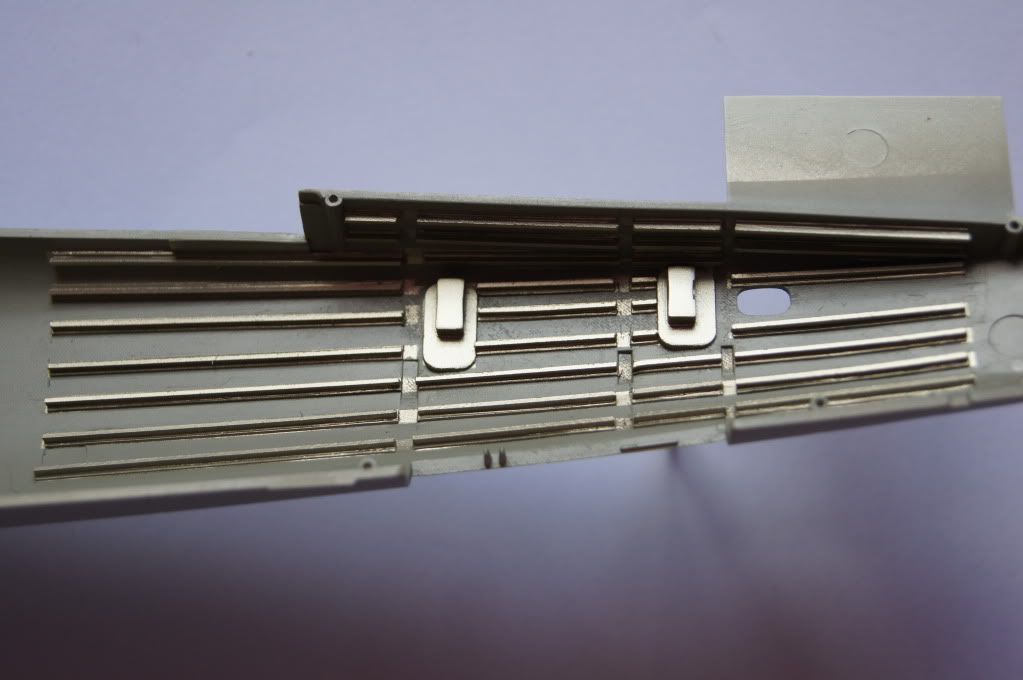

Main landing gear supports has the eduard treatment, and will be blessed with RLM02, then a COAT OF Alclad ALC-104 Pale burnt metal. This is to represent the electrolised finish on the ribs and main inner parts.

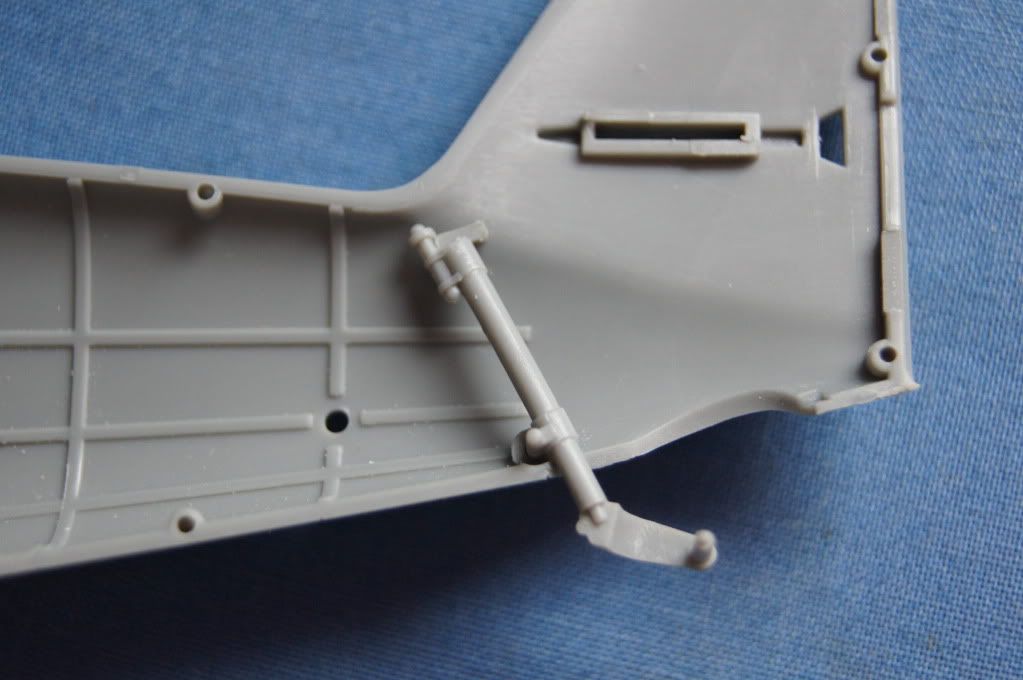

Rear landing gear leg eduards PE on.

The main wheel well detail was removed and, the detail replaced with eduard parts from the big ed set. These parts need working by trimming some parts to get them to fit. I keep them propped up by white tac. This help as i use thin superglue that acts like extra thin cement.

The fuselage was painted rlm02, then the ribs painted, Alclad pale burnt metal (ALC-104)

The large pipe is the fuel dump pipe.

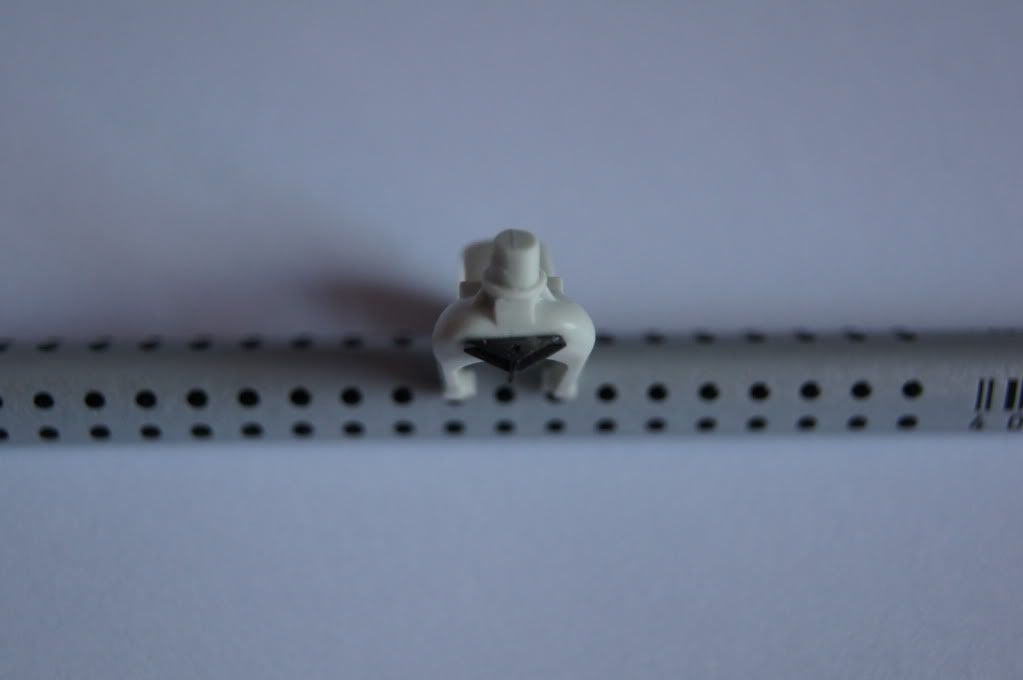

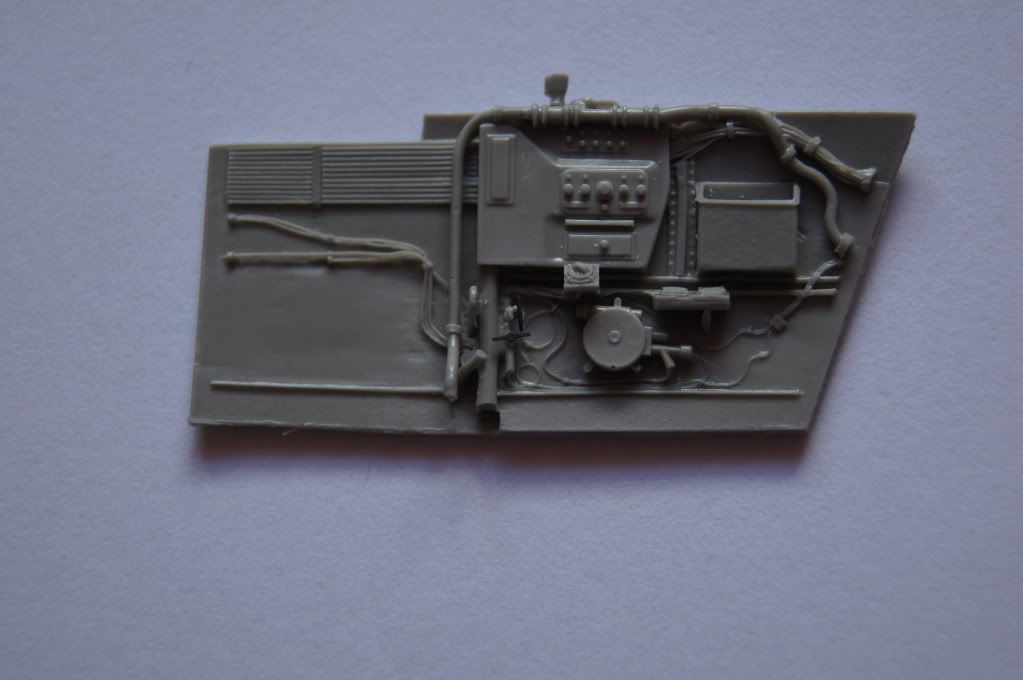

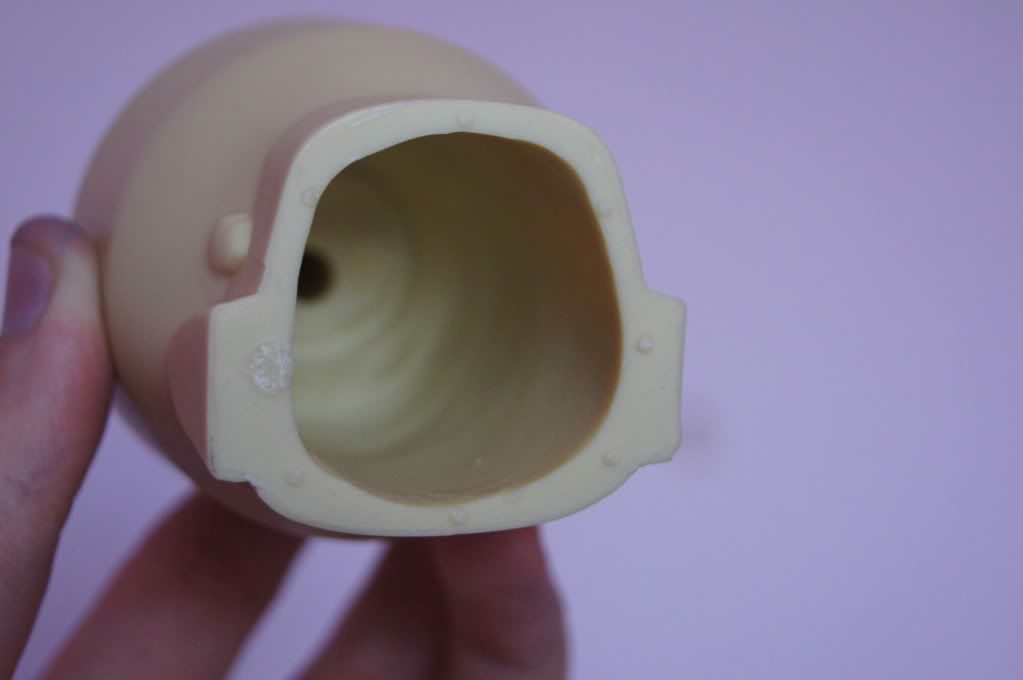

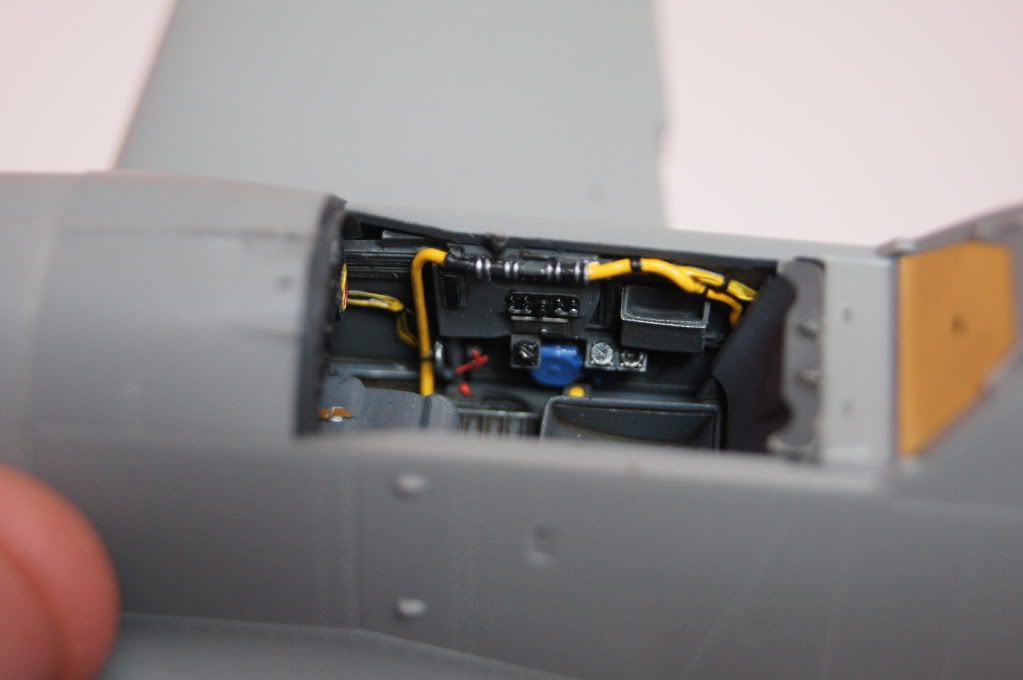

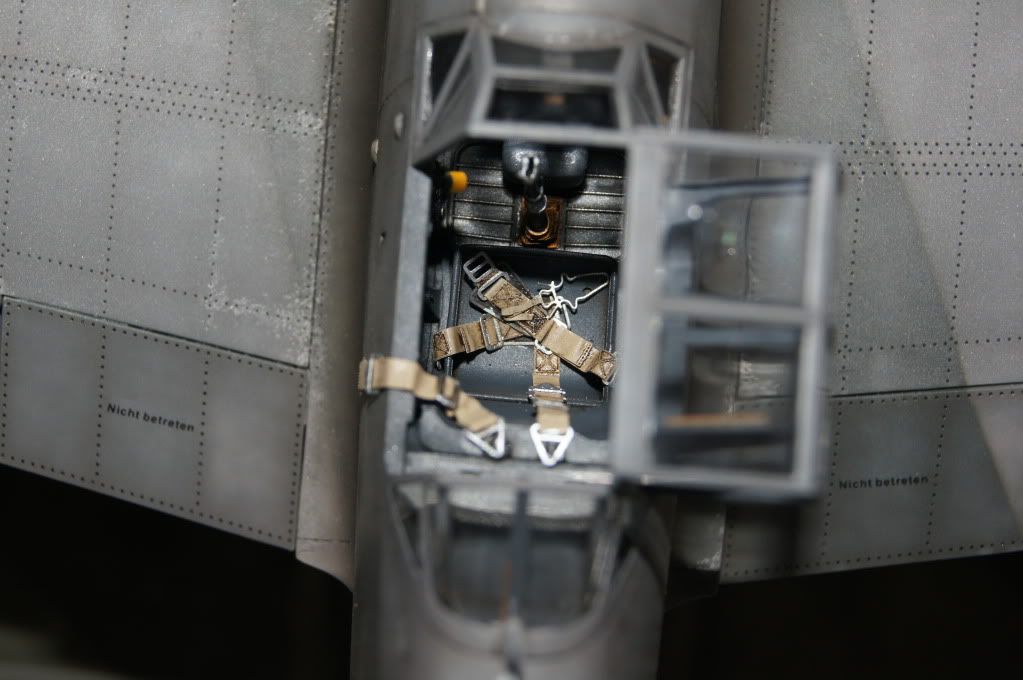

The aires cockpit set for the 109 ready for paint.

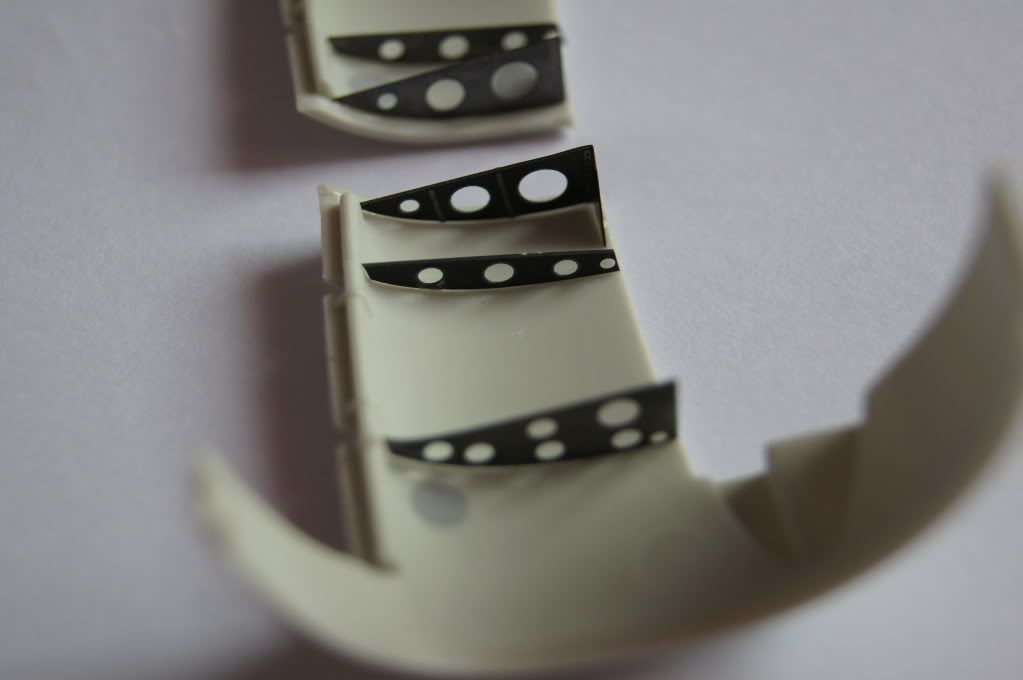

Armourd head rest with kit photo etch and, aires photo etch attached.

Aires seat belts. These were all photo etch that needed to be threaded through other pieces of photo etch.

Im in the process of trying to paint while throwing up and im starting to get into a rythum. It gets a bit tricky when im spraying alclad, and i've got my paint mask on

A bit all over the place at the minute, but i've managed to do some more on the JU88A-4.

Both main wheel wells have been completed, all that is required is some weathering. I will do this when the model has been painted.

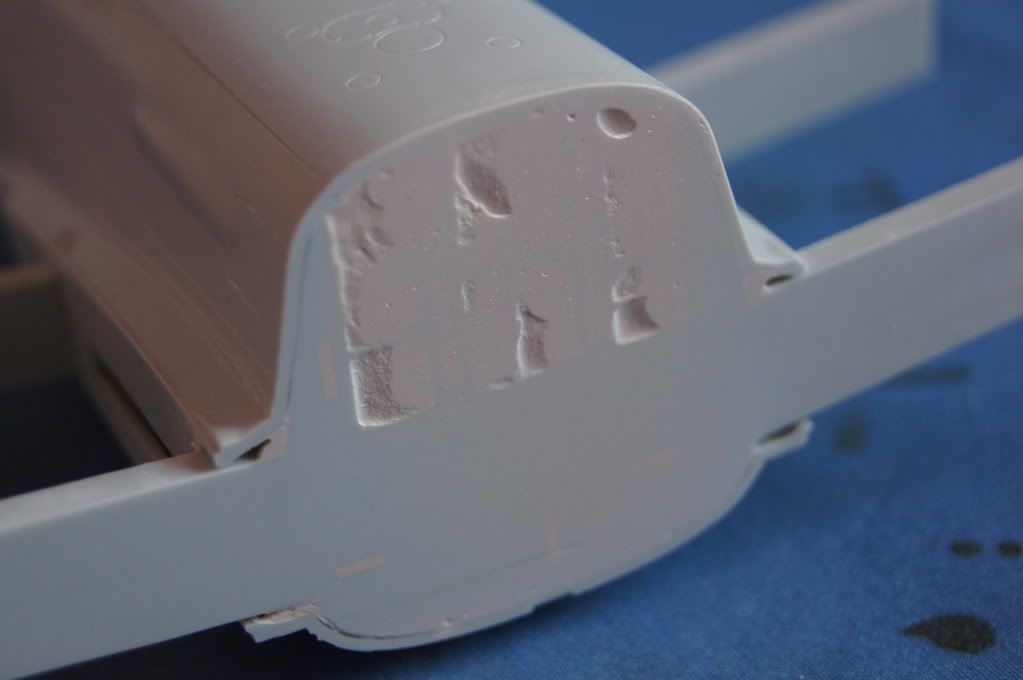

When i completed my first revell 1/32 ju88 i did'nt fix the problem of being able to see into the engine compartment. So i have found how to make a simple bulkhead,

Some people would cut a piece out of plastic card with a compass cutter, but the shape of this front area is not perfectly round. What i thought of, and actually worked was painting the front area of parts, (C49, C52), any acrtlic paint and before it dries, placing it on the plastic card. This made what looked like a coffee ring sort of affect. Then i cut it out and,

hey presto, when painted silver you would never know.

I've also finished the engine necells parts, (E97, E98, E99).

These are the engine instruments, that only face inboard. The dials are from the eduard big ed set.

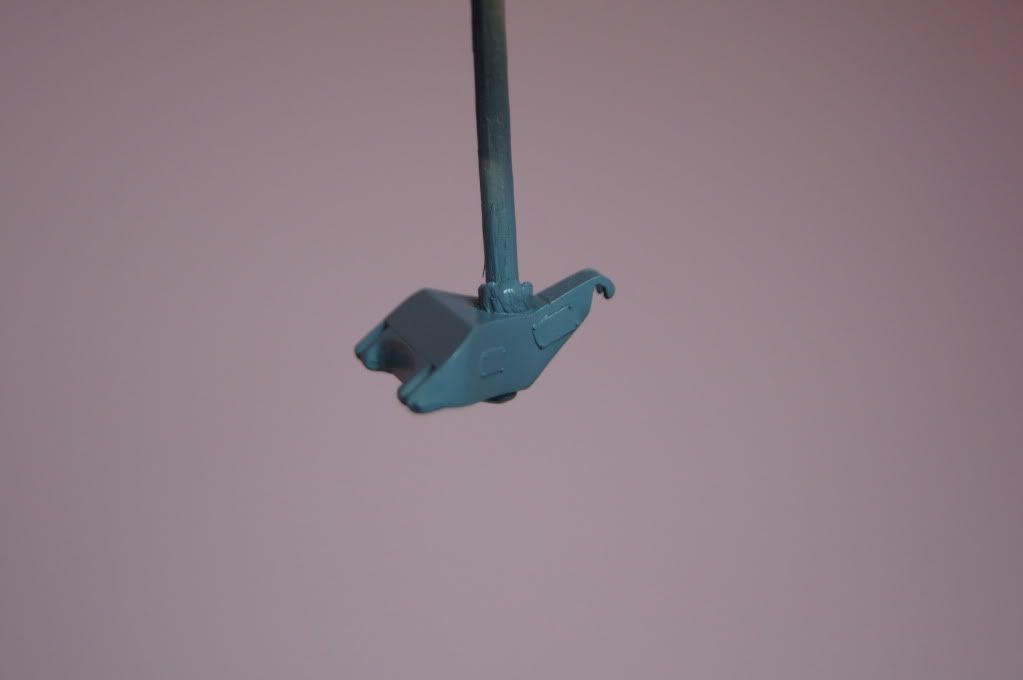

The rear landing gear, painted with Gunze H53 neutral gray and Tamiya X-23 clear blue, it was around 8-10 drops of H53 to, 1-2 drops of X-23.

By Monday the fuselage will be done, also some suggestions of how to glue the huge bomb that weighs, about the same as three pots of full tamiya paint, will be appreciated . After that the build should move very fast indeed. If only this was a tamiya model and i wouldn't need to detail as much.

. After that the build should move very fast indeed. If only this was a tamiya model and i wouldn't need to detail as much.

This is what i mean about the huge resin bomb. This is the total surface area that'll be glued onto the JU88! . All i can imagine is sometime in the future it'll fall off.

. All i can imagine is sometime in the future it'll fall off.

Ok this is where i'm at the minute. I'm now waiting for the epoxy glue, cummon mail man, where are you

The rear wheel well is complete.

BF109 dashboard complete.

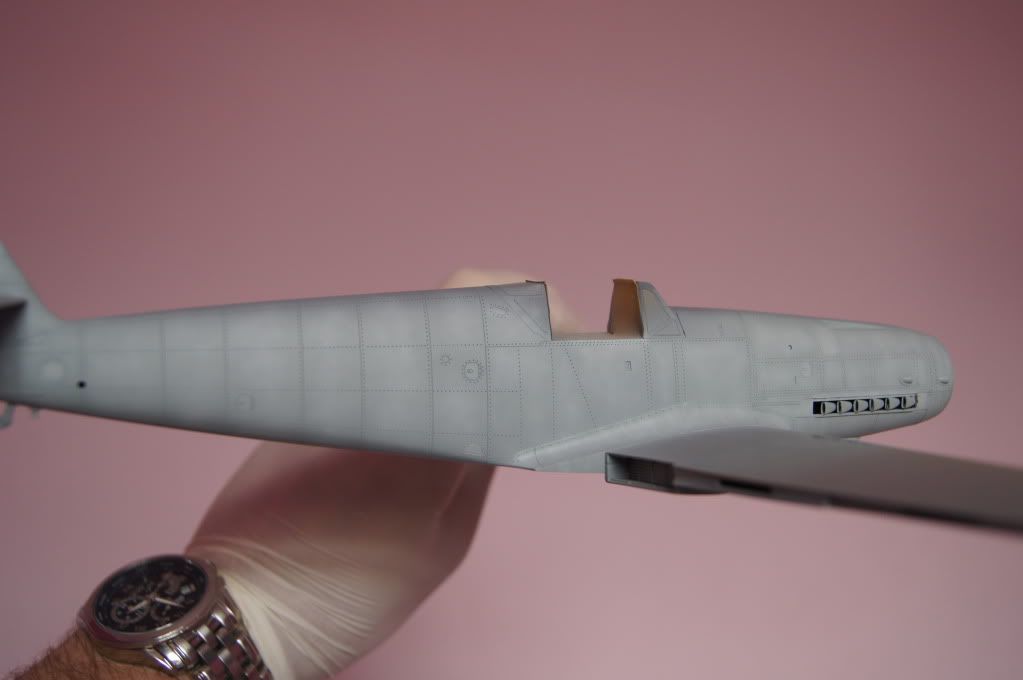

The fuselage is complete, and fully rescribed. I used epoxy putty used for cars on the front of the fuselage. I didn't make a real perfect job because, all i wanted to do is fill most of the gaps.

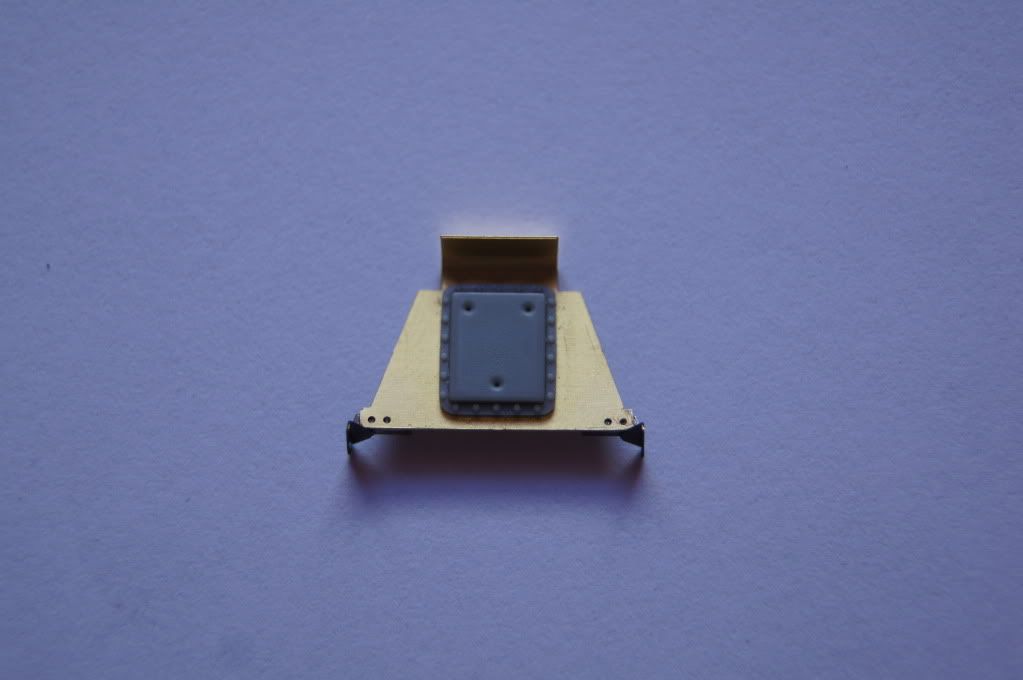

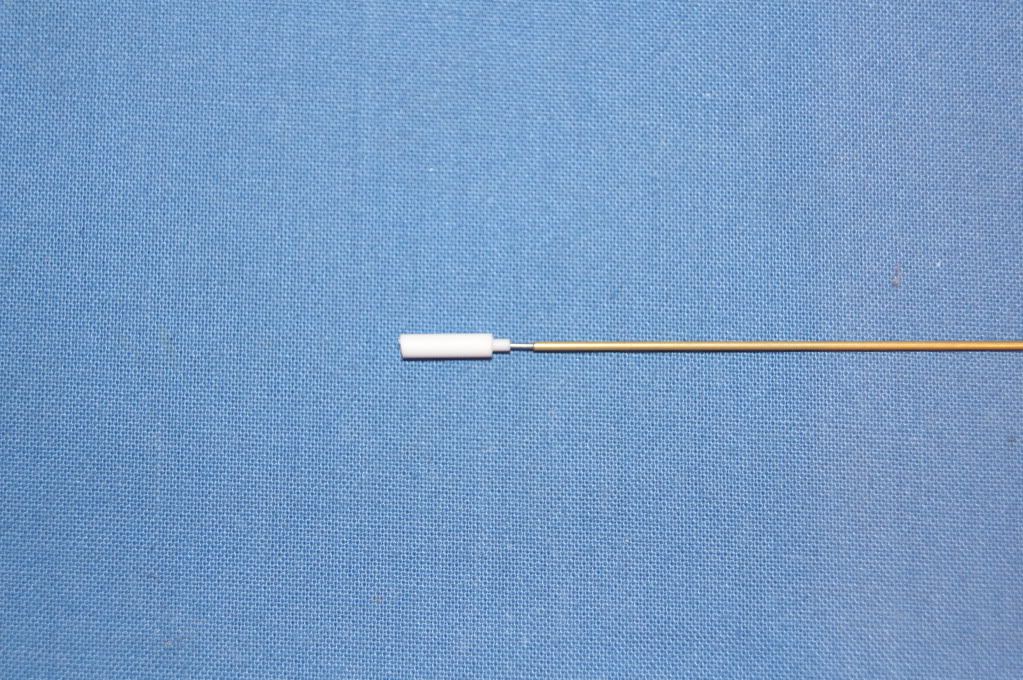

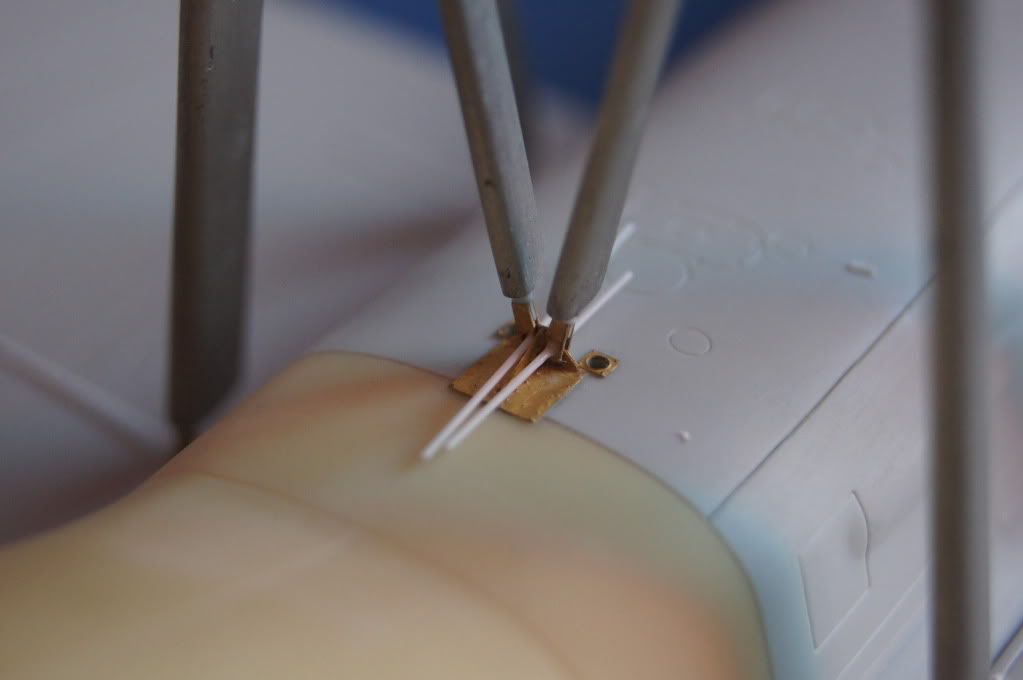

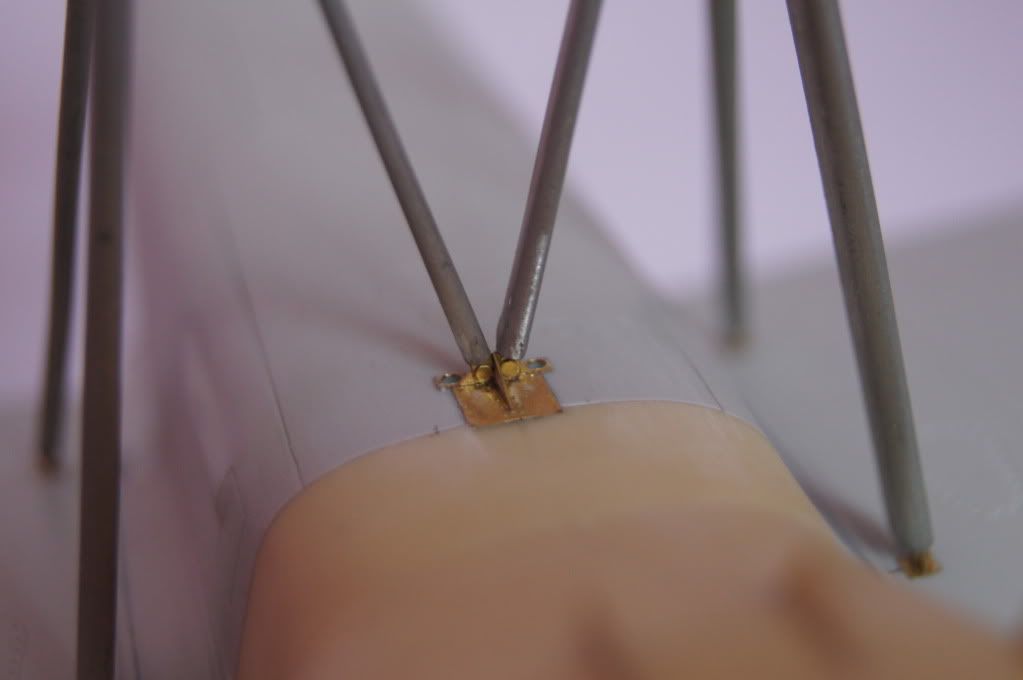

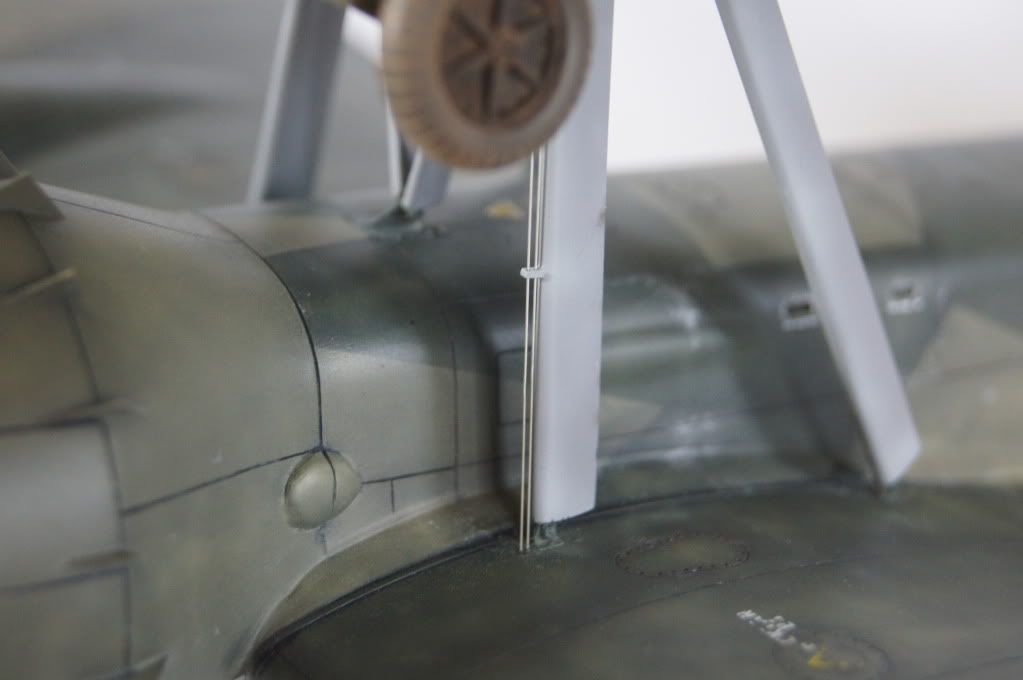

This is top of the scratch built rear strut, that holds the bf109. The brass tube is 0.8mm wide, the silver is fuse wire and is 0.6mm, and the plastic rod is 1.2mm and 2.0mm wide. The bottom will be connected to the ju88 by an upside down T. The strut bottom would resemble a n shape, and the two will join together with a bolt through. All the struts front and back are held to the ju88 in the same way.

This is where i was upto from last night.

Ok last week the very kind postman gave me this,

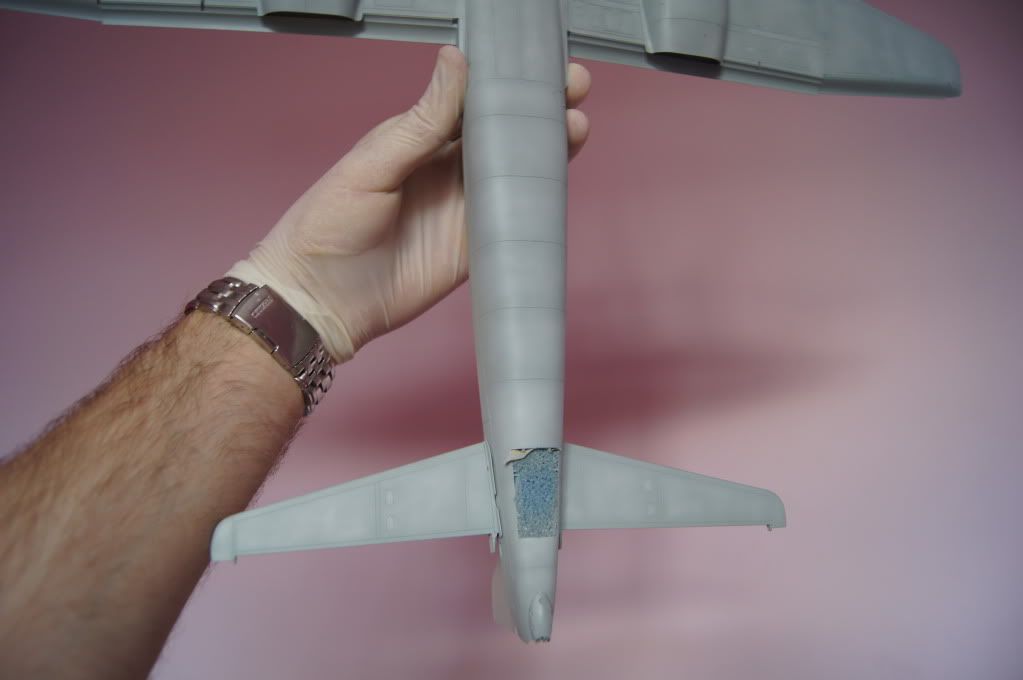

I've managed the glue the very large bomb onto the fuselage, like it says on th box it only took 5 minutes. I can actually shake the plane while holding onto the bomb section, which is great.

The joint is nearly perfect, as the bottom section needed some filler.

The wing to fuselage needed some slight help with gunze mr surfacer 500.

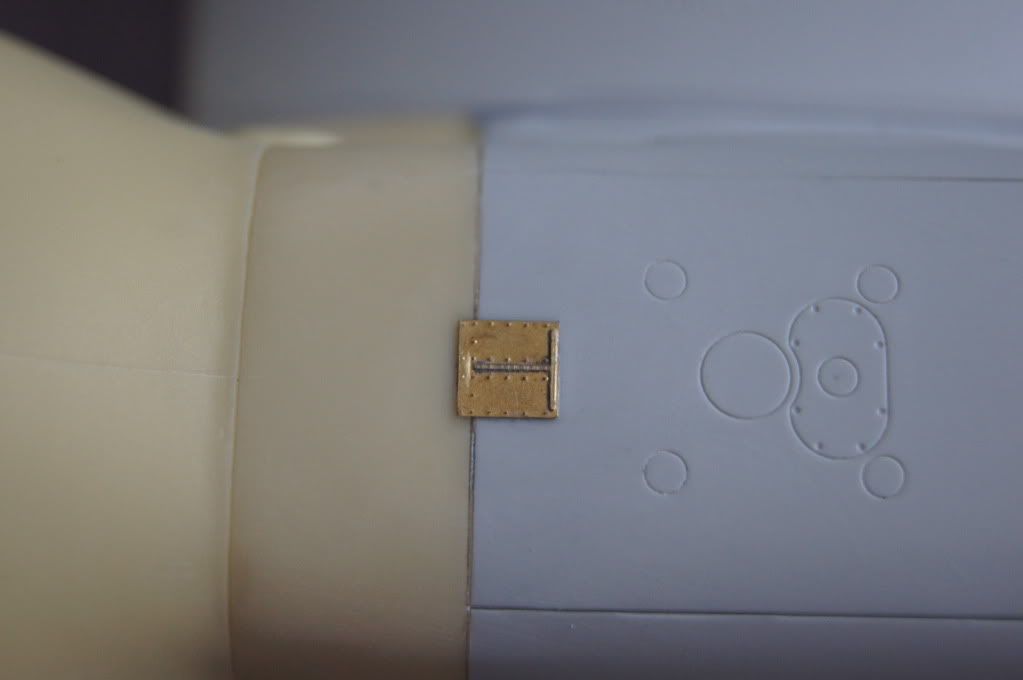

I glued on the PE plate that holds the v shaped bracing in place. This was glued using the epoxy glue.

Then the corresponding square PE parts were glued in place. The centre hole in the PE part being drilled out, to accomadate the fuel pipe (on the right hole), and electrical cabels, (on the left hole).

I used my trick that i have mentioned earlier, by using white tac, to hold the PE part in place and upright. Then by tacking in place from the other side with thin super glue, i removed the white tac.

Finally the last piece was the triangle PE part. This was glued the same way.

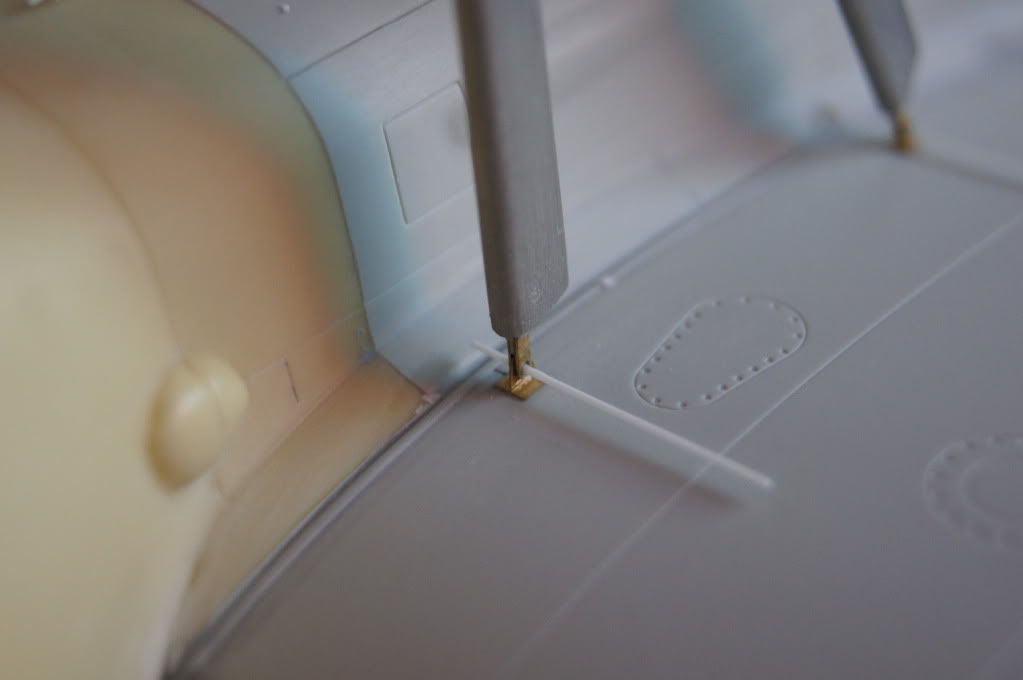

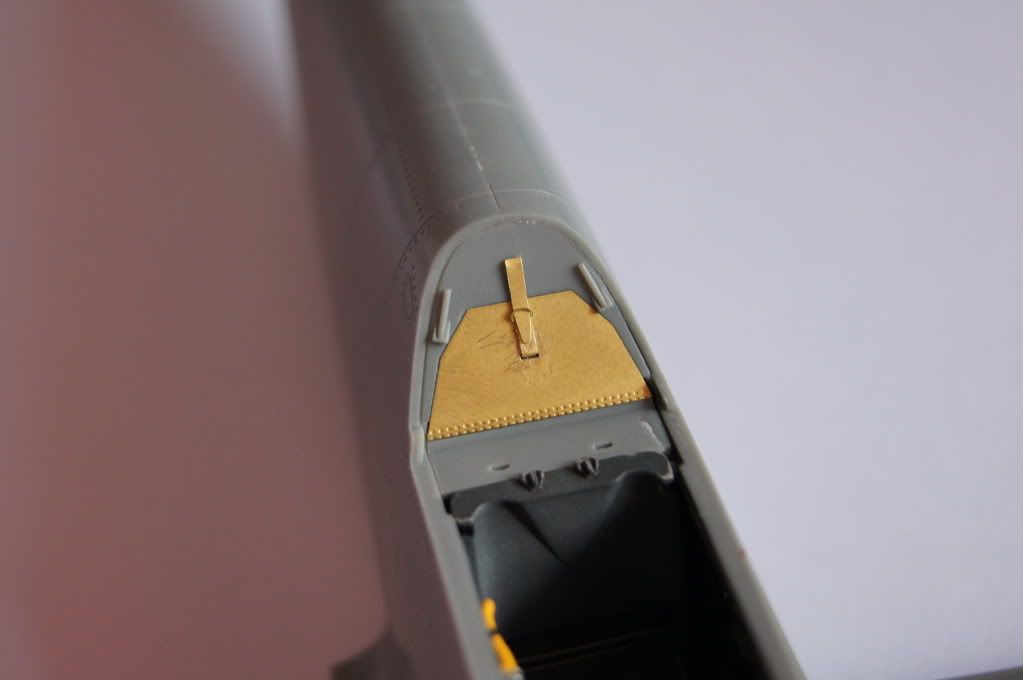

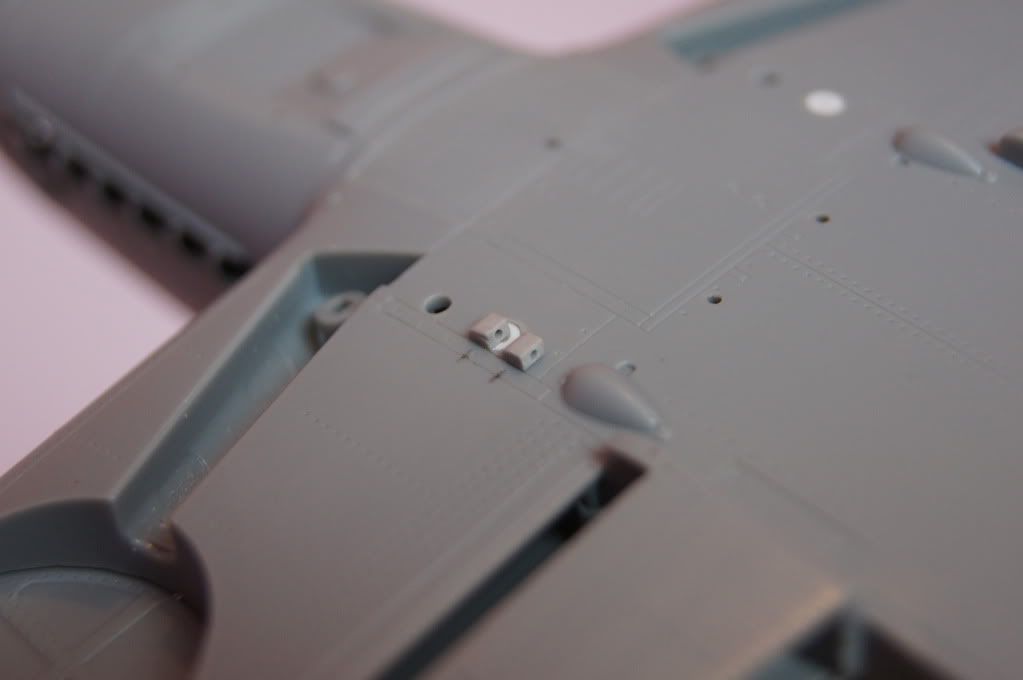

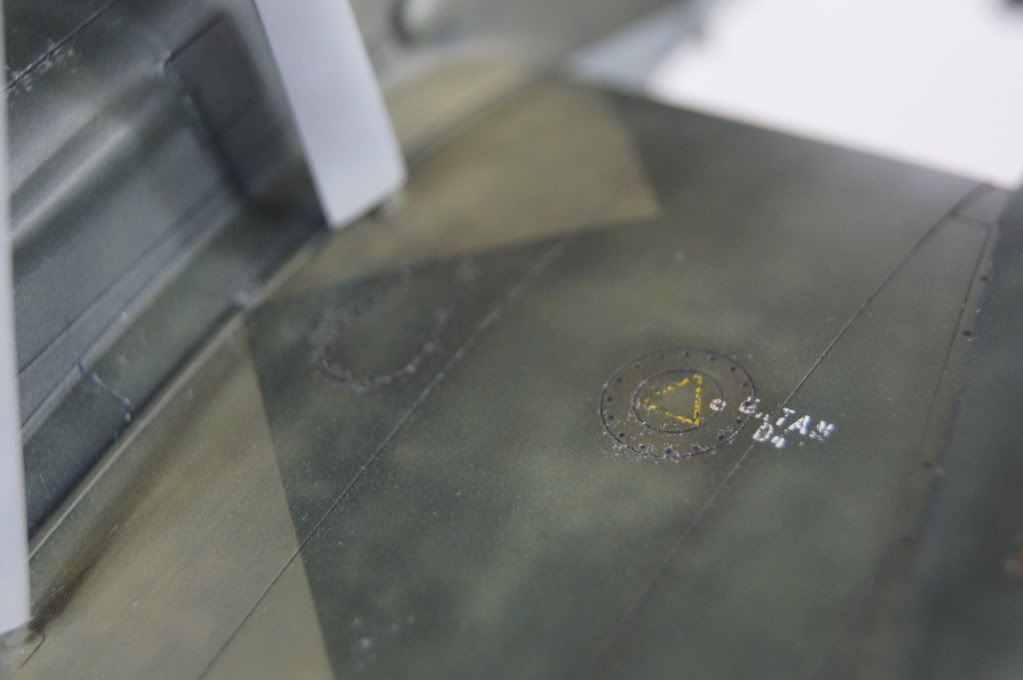

The rear brace bracket was glued just behind the first clear part, (I 40), and on top of the dinghy hatch.

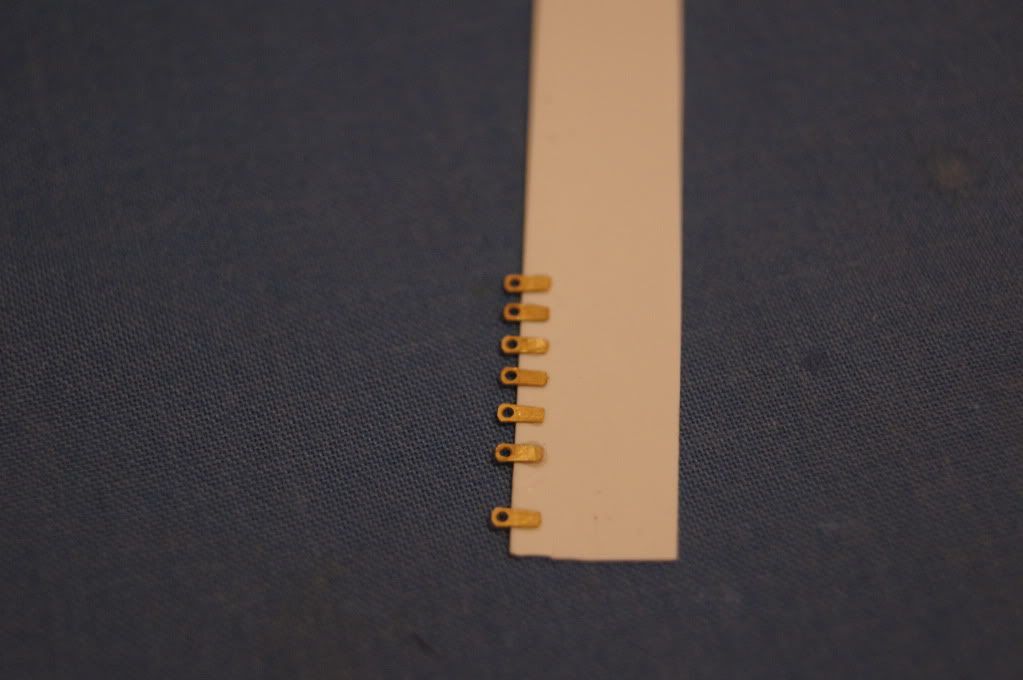

All the PE parts for the lower struts were glued to some plastic card. All will be made clear why in the next photo.

Then the corresponding PE part was glued onto the other side of the plastic card. A piece of copper rod was inserted between both holes to gain better aligement of the parts. The excess plastic card trimmed and sanded to represent this.

The same as the rear fuselage bracket but slightly bigger, as it's gotta hold, all the bracking itself and the weight of the bf109. The PE plate in the photo was placed 1mm from the ridge on the wing.

The rear bracket was glued slightly further away from the wing/fuselage joint, and it also was slightly angled towards the front bracket.

Tried to take a photo of them both but it just made them both blired, sorry.

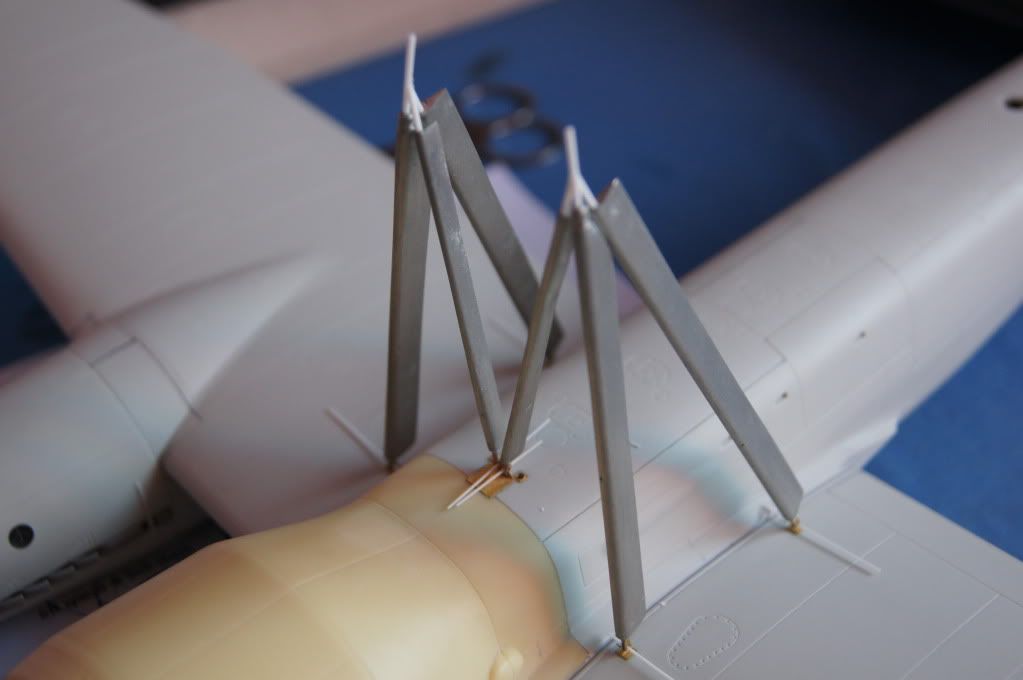

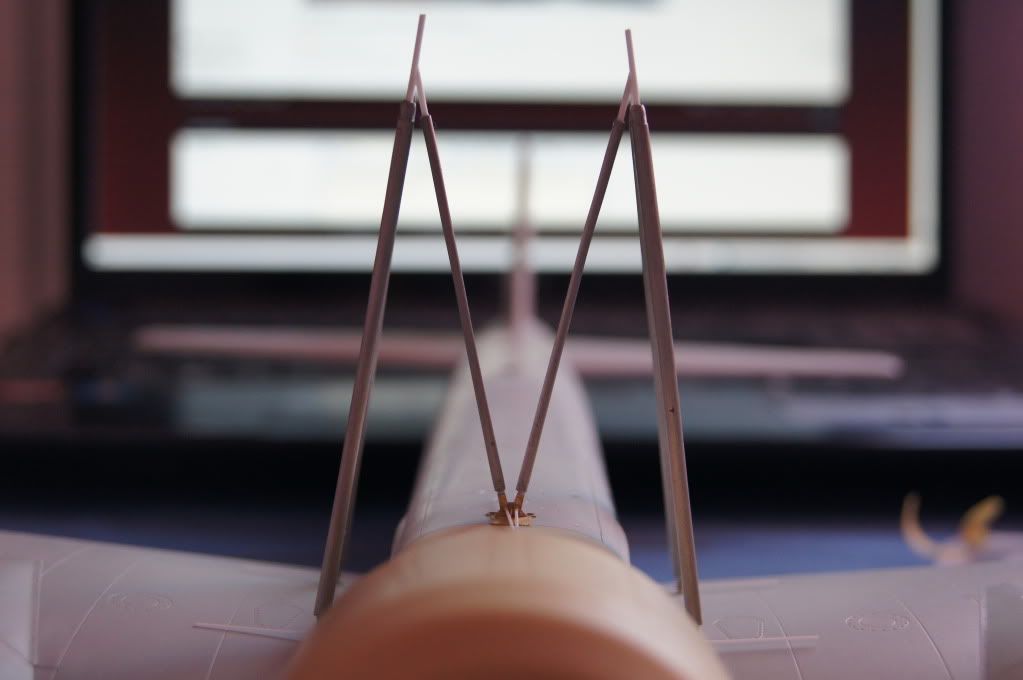

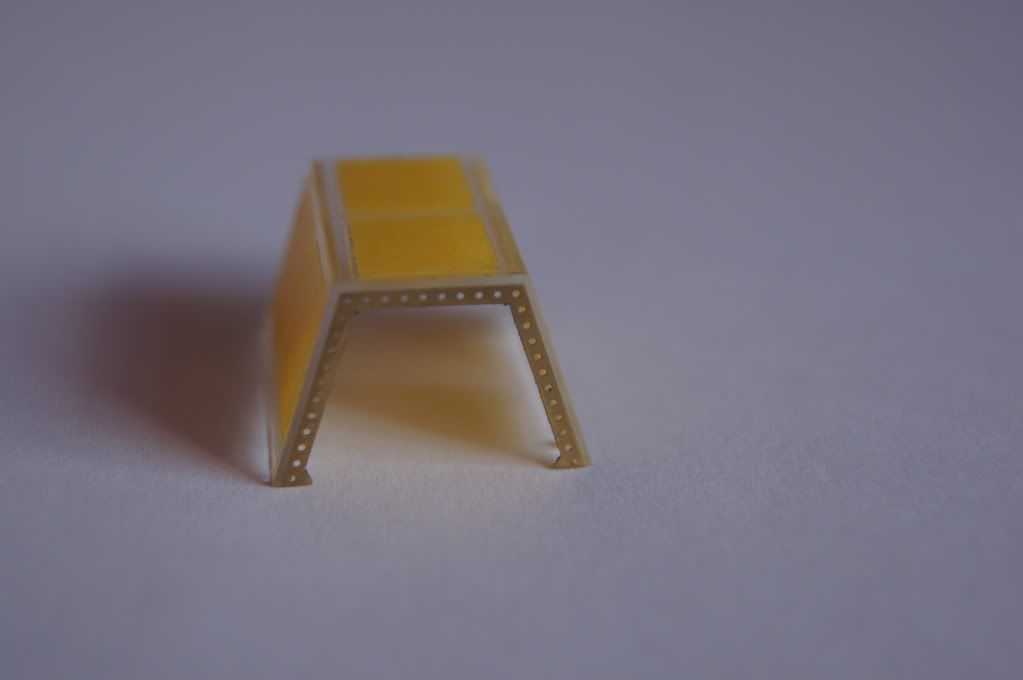

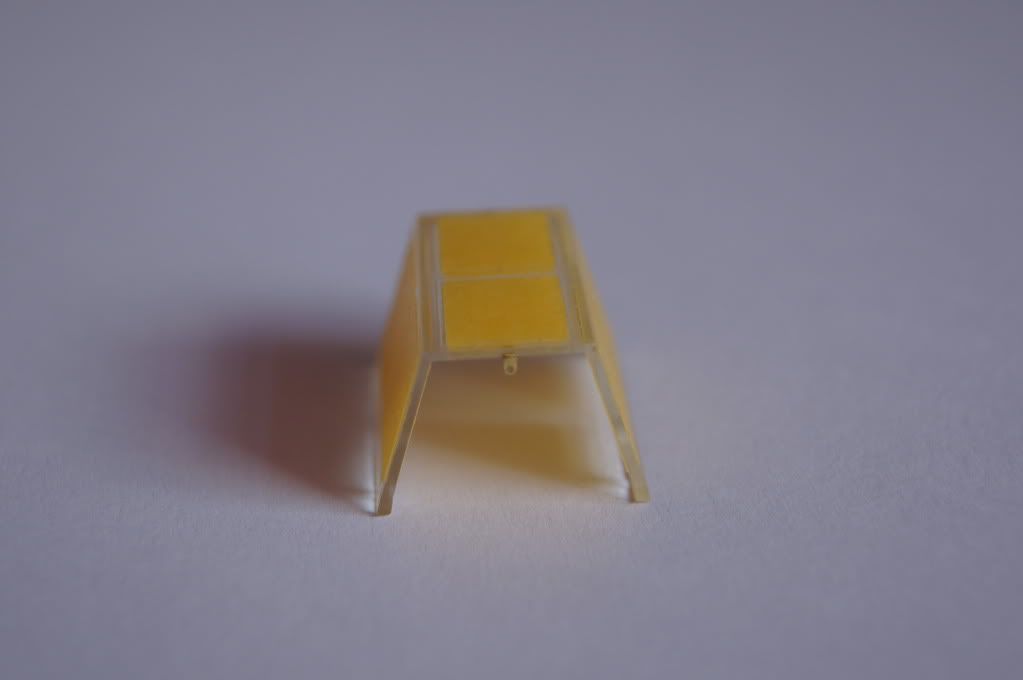

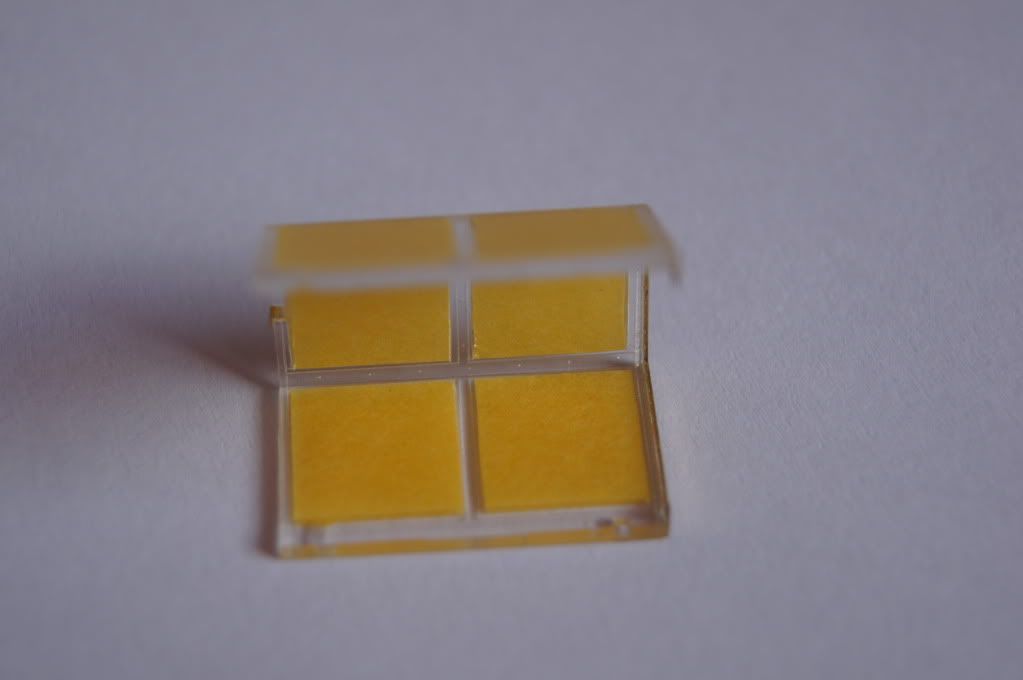

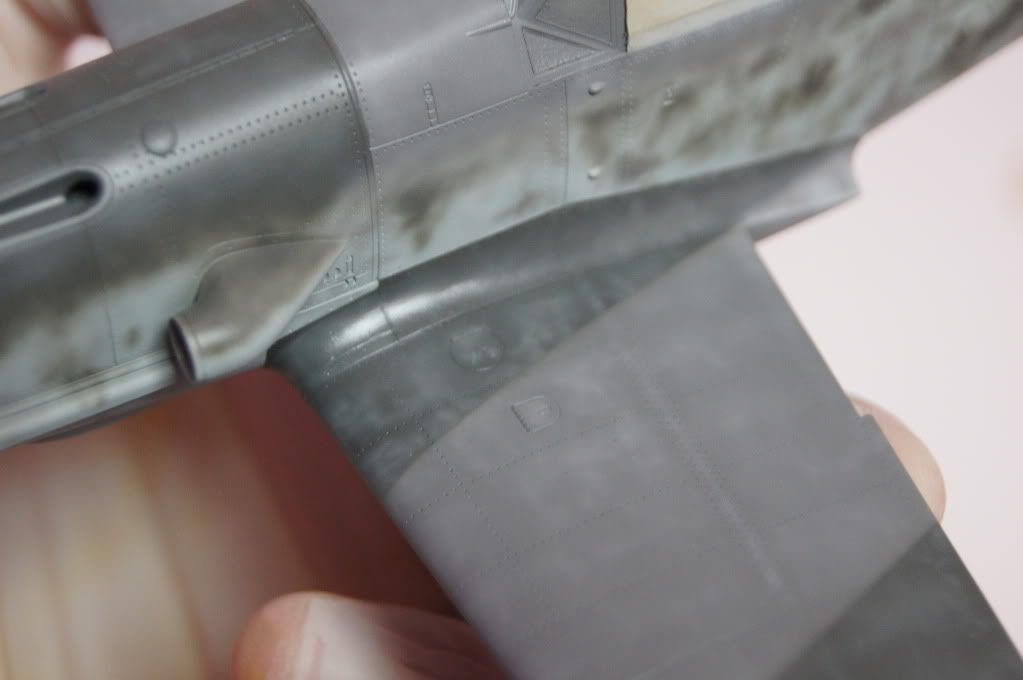

Completed the cradle arms. The two larger are the wing rear arms. The middle two are the front arms that point straight up, but at the same time are sloped inwards. The last two on the right are the v brace that holds it all together.

The n shaped connections are glued onto the cradle arms, so that these will connect onto the brackets on the wings and fuselage. A bolt will be placed between them, and a nut from each end. Hope it stays up

I managed, with a bit of fiddling to get the cradle on. The spacing between the left and right cradle should be 3.2cm, and should sit around half cm behind the bf109 landing gear.

Ok thats the cradle on, phew

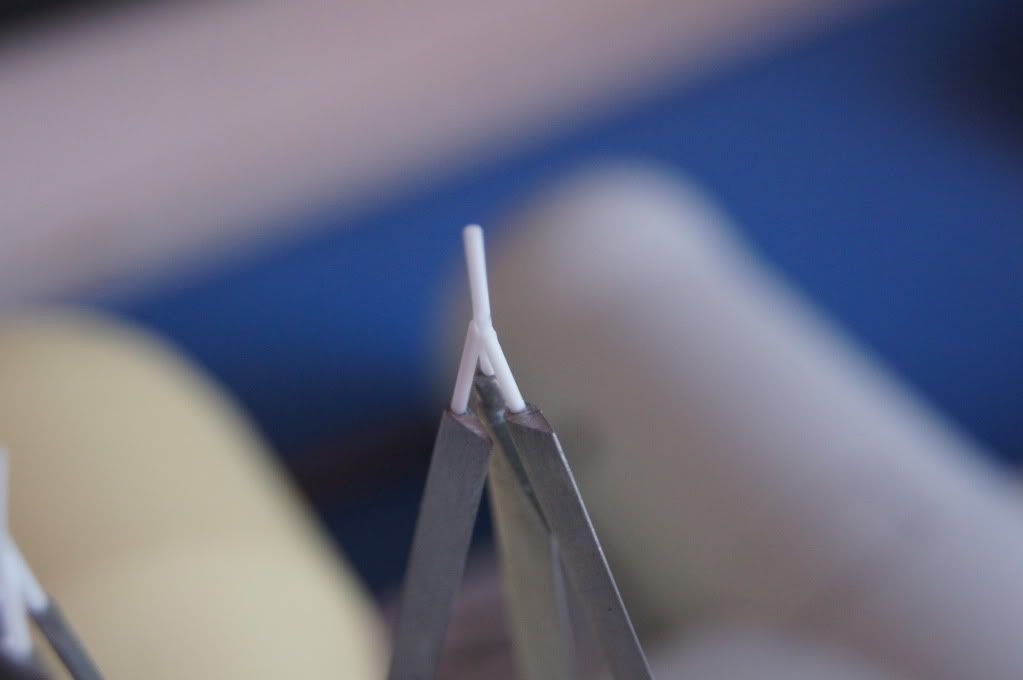

I changed my mind and used 0.88mm evergreen plastic rod to hold them in place, as i thought that fusewire, (around 1mm thick), would be very difficult and hard to cut later.

These plastic rods will be cut and the hole convered up by PE nuts.

The cradle is slightly slanted inwards, and at the tip, it should b 3.2cm wide. I had to cut the v brace off from the 2 side A braces, because the gap at the top was 4.1cm throwing everything out of balance. A bit of proding and poking here and there and every sat neatly. It was a bit of a heart stopping moment.

The left A brace.

I also replaced the top connection pins for each brace, as i had glued brass tube, (0.8mm), and found it very hard to work with and possibly hard to glue when i start to assemble. So i replaced this with 1mm evergreen plastic rod, so that i could just use tamiya extra thin instead. I think it's gone well and it should hold the bf109, even though i had my doubts a few days ago.

The 109 is not glued, but i think it's about 3-4mm too high. That is what the drawings from Waldemar Trojca vol 2 of the ju88, is telling me.

I have been working on the bf109, while doing the ju88. As now i'm playing catch up due to the cradle crisis.

The rear landing gear for the 109. Should be very sturdy, but i doesn't need to be sturdy for my model.

The cockpit is complete, the aires cockpit tub is awsome.

I haven't yet completed the cockpit, as the seat belts have to go in and the gun sight. Plus some more weathering from mig pigments, to represent mud and grime.

There is nearly no wing - fuselage gap, apart from the fromt section on both sides. The engine is a loose fit as the engine mounts have nothing to be fixed to, so the exuasts don't stick out that fare.

A few more days and both models will be ready for paint.

I'm nearly done the construction part of the build, i should be soon moving onto the painting stage.

I have mostly been putting off this next part of the build because i thought it'll put up a fight. But actually it suprised me when it went right first time

I think these spines are for stability control, thank god they didn't put up a fight.

As you can see, i've put all the nuts on the ends of the bolts at the base of each strut.

I've also built the JU88 landing gear, and prepped the Aires wheels which are provided with masks.

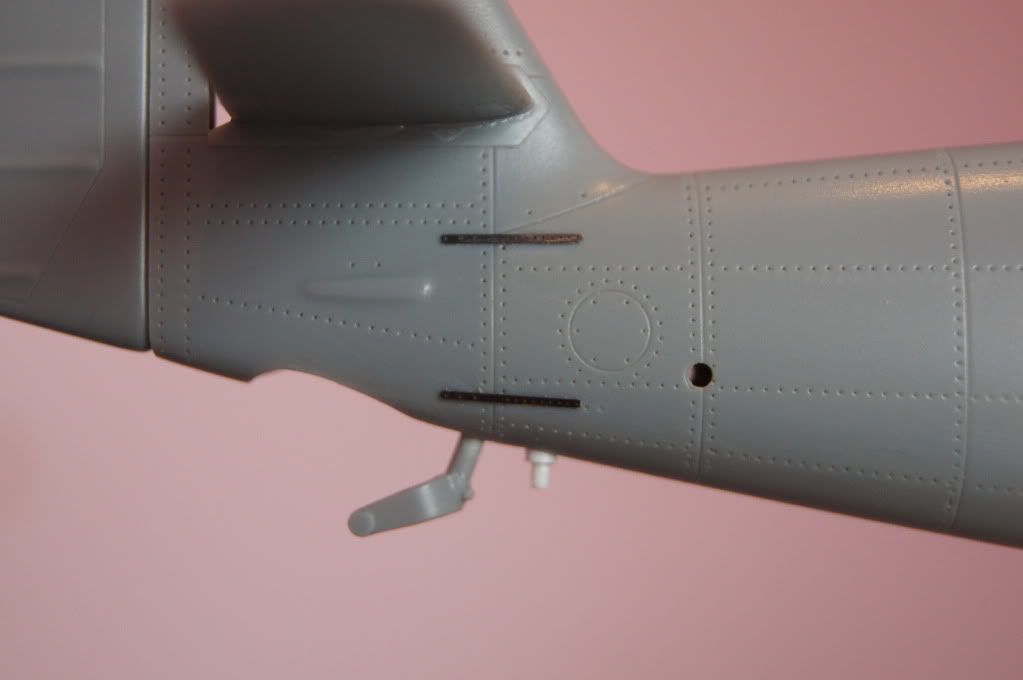

The supercharger air intake has some small gaps, but i think that was mainly my fault. Also i haven't included the machine guns or canon, because the mistel did'nt carry any armament. This was mainly due to weight concerns, as the mistel was too heavy and even had to be towed onto the start of the runway, in case the mistel toppeled over, which many did.

I did drill the holes in the wrong place and too big. So i drilled the holes due to my interpretation of photos of the real aircraft.

Just some more prep work to do on the 109.

All the kit PE parts added to the canopy parts, plus i've masked the canopys inside and out.

The kit proprllers are not the right shape for a 109F, so i've used quickboost 109F propellers which are a direct perfect fit.

The kit landing gear should have kit plastic brake lines but i lost them, so i replaced this with fuse wire.

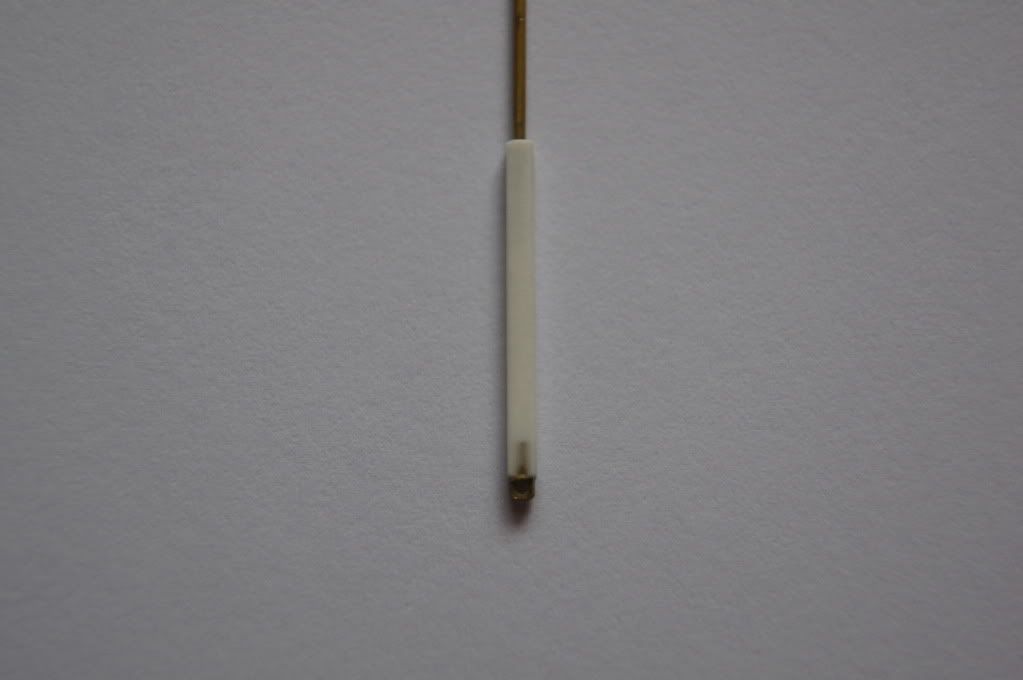

This is the rear strut that'll hold the rear fuselage of the 109. The total hight from the top of the ju88 fuselage to the top of the strut is 7.4cm. The white bit in the photo is 2mm round plastic rod, that is shaped into a square.

The ju88 land gear. Wire should be connected from the middle of the PE part, to the top of the landing gear.

0.75mm thick plastic card was used to make holders for the flying controls. The two cabels control the ju88's elevator and aileron's. When the two aircraft seperate, the pilot in the 109 can control the ju88 with two handles. They look a bit like two T shaped throttles and control pitch and roll, a bit like a wire guided missile, and this was back in 1944 .

.

The tires are around 1mm wide and 1.5mm long.

At the front of the bomb are 4 Electrical crush fuses. these are seperated up/down, left/right by 4.5mm.

Just behind these fuses is the stand-off pobe, then the hollow chamber. The main bulge is where the bomb lies. This consists of a forward part which is a soft metal liner, then the main explosives and at the back the Detonator. When the ju88 hits on impact, electrical crush fuses operate detonator, which sets off the explosives and causes the front metal liner to form a Molten jet of soft metal. In essence like a anti-tank rocket, but with a lot more kick.

The light is'nt a bad fit just needs a bit of fiddling.

I managed to find a big enough drill bit for the rear strut's location hole and i still had to make it bigger with my round files. Also the PE parts are from the aires cockpit set.

and i still had to make it bigger with my round files. Also the PE parts are from the aires cockpit set.

The canopys on, but the rear one caused some problems. I had previously dipped these in Klear so i could use superglue, sand and re-scribe the panels back in.

The top of the engine cowling should have a hinge, to enable acess to the engine. Two panels lines were scribed equal length, then 26 lines scribed between them.

The rear strut is 3mm forward of the rear gear leg.

These two boxes were scratch built from an old resin cast block. They are the electrical connection points between the 109 and ju88.

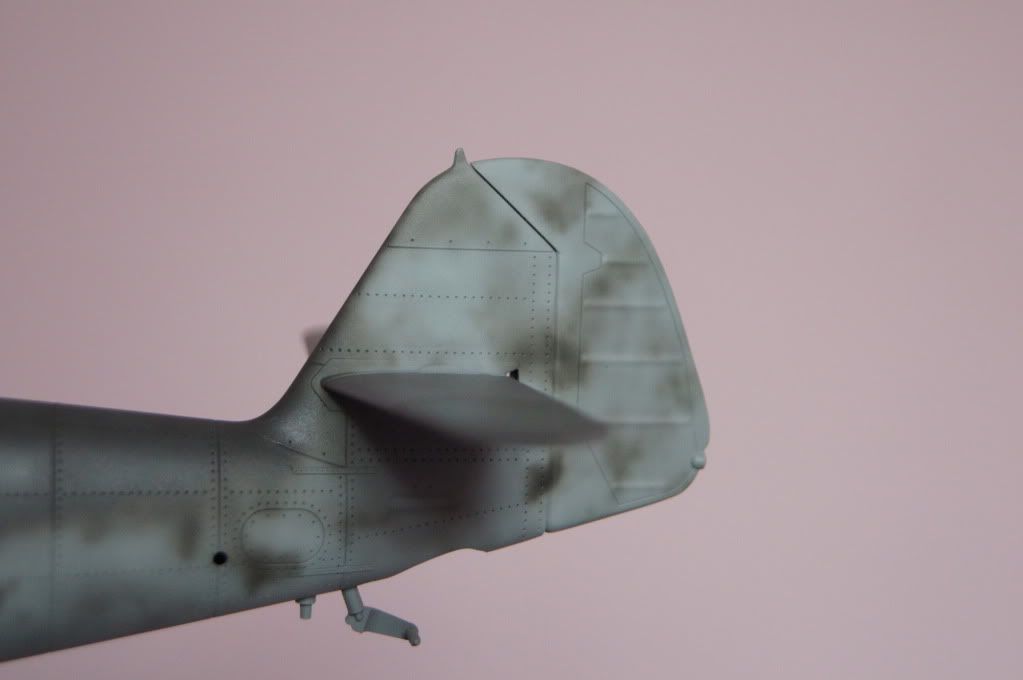

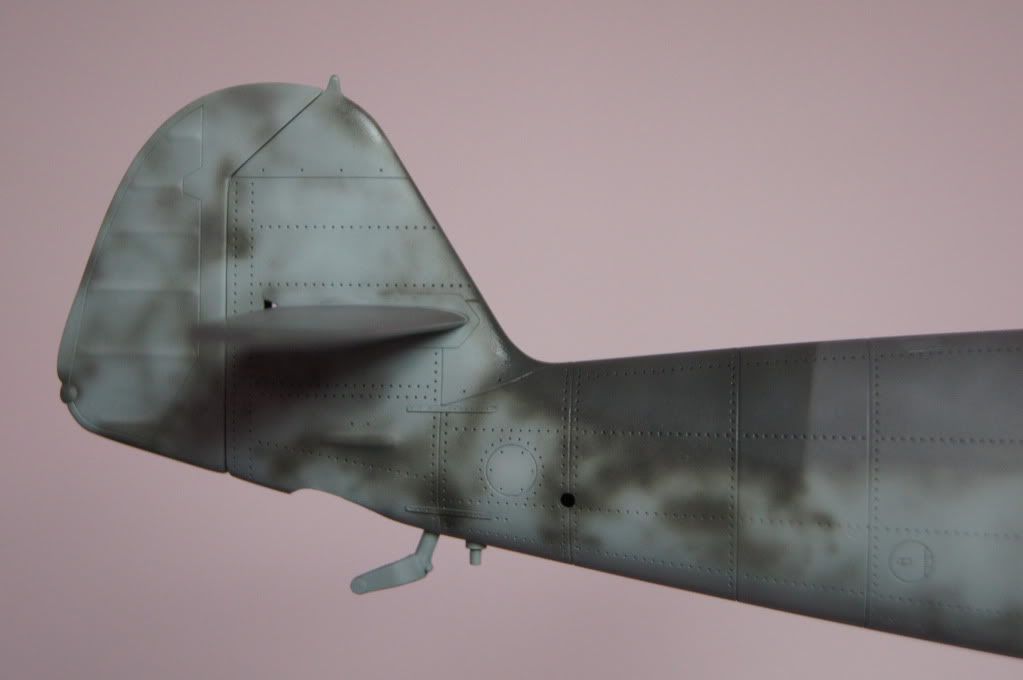

I first sprayed the RLM 76 and tinted and faded the paint on both aircraft.

Then disaster struck, after masking i spilled the RLM 71 all over the mask and it ran underneath. So i had to wait untill dry and sand back, then i resprayed the colour.

Also i got carried away, before i knew i had painted both colours and mottled the 109 without taking any photo's, sorry about that

I have started to think i have made a mistake by gluing the cradle on, it is causing problems painting, if i did build another i would paint first.I first sprayed the RLM 76 and tinted and faded the paint on both aircraft.

I have started to think i have made a mistake by gluing the cradle on, it is causing problems painting, if i did build another i would paint first.

I have been very busy getting the paint job and weathering just right with what i think is right for the period.

Also i knocked the cradle off the ju88 twice

, and the second time i knoked it off i had a problem when i placed the 109 on top the wings weren't level. So i had to put a very small amount of plastic card to raise the left wing. I have the most of the painting done and most decals on, i think it's time for some pics.

, and the second time i knoked it off i had a problem when i placed the 109 on top the wings weren't level. So i had to put a very small amount of plastic card to raise the left wing. I have the most of the painting done and most decals on, i think it's time for some pics.

I used Gunze RLM 71 for the first colour which is quite dark, but don't be fooled it's a lot lighter than the RLM 70.

This shows how dark the RLM 70 is, i also painted the cradle with Gunze RLM 75 and the square on the fuselage is Gunze RLM 02.

I wasn't happy with the mottling job on the 109 so i tweaked it a little. If the paint is thin enough you can spray again and again to get the mottling right.

I totally forgot that i needed to spray on a yellow band on the fuselage, this should have been done before any of the painting. So i had to paint white first, this makes it easier for thee yellow to be applied and in a thinner coat.

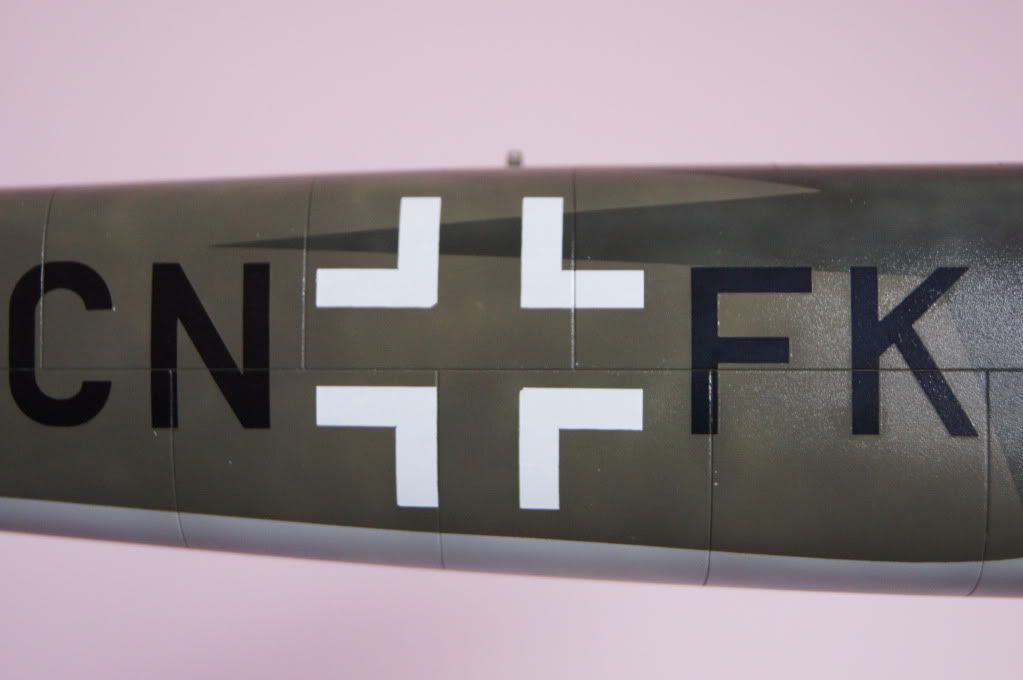

The yellow sprayed and decals on. The white fueslage cross needed the centre painted with RLM 75 and i also faded the paint to match the rest of the aircraft.

The decals applied and ready for weathering

Also some decals applied to the ju88, the swashtika on the tail showed through the white 1. So i had to mask and over spray the number 1, all this after a coat of Johnson's Klear.

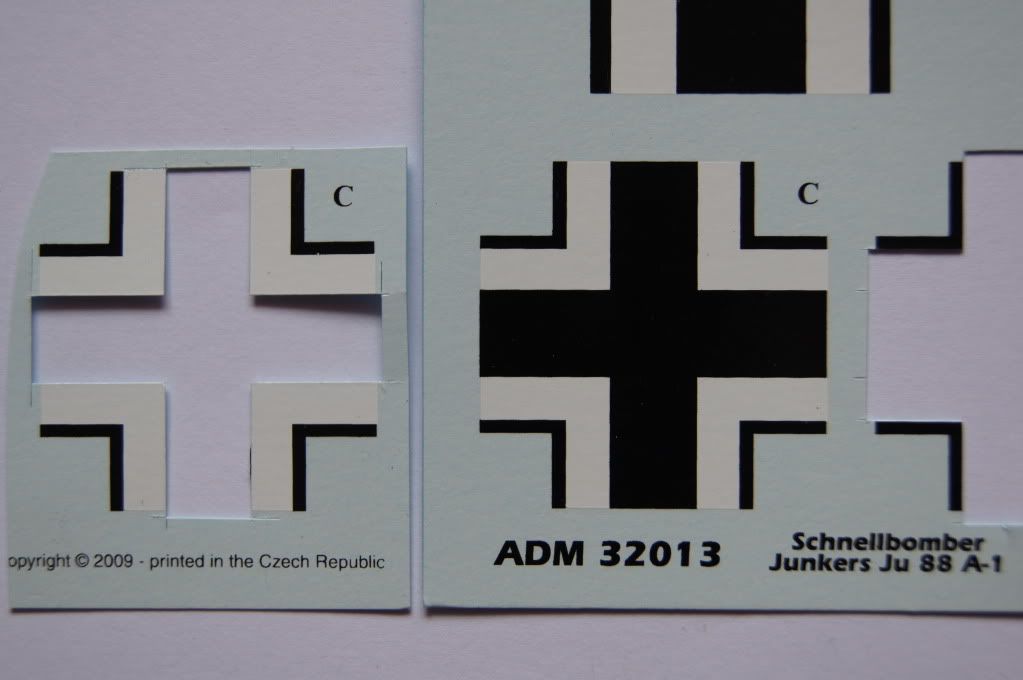

The white cross for the fuselage didn't exist for the ju88 and Aims don't provide this in the larger scale. So i had to be cut it out of another one that has the black inner and outer parts.

These are the Airdoc decals and 2 decal number c's were sacrificed for the fuselage crosses.

The one on the right is the original, and the left one is partly butchered.

Kits world decals were used for the white croses to the top of the wings and fueslage of the 109. These decals are supurb very thin and react well to the set and sol treatment.

This is unknown but some sources say that the 109 had a black and white spinner. So i painted it anyway.

It doesn't show it that well but i have faded the paint on the 109 propeller blades, later i will use a silver artists pencil for chipping as the 109 had a metal propeller.

Done the same with ju88 propellers but these are originally made of wood, so no paint chipping.

All the same with ju88 spinner.

The ju88 landing gear was a bit tricky, as i had to paint the Alclad Pale burnt metal ribs and then mask for the silver.

After painting the Trumpeter kit wheels i tried to put the hub in place within the tyre, but it ripped off paint. I have never liked rubber tyres so i bought Aires resin wheels, that make a huge improvement.

Majority of the ju88's parts painted and waiting for weathering.

The 109's main canopy is complete and all it needs is some more good old weathering.

So the last progress pics for my last entry to the group build.

I thought i might have a problem with the antenna mast, as the point of connection is very flimsy.

So i had to drill a hole in both the canopy and base of the mast, and put some fuse wire in to provide rigidity.

As i had not pre-shaded the aircraft's, i generally find post-shading easier to control and looks more realistic. This was done with a very thin mix, (around 90% thinner to 10% paint), of Tamiya red brown and gunze flat black.

What i do is use the handle end of a brush to put two drops of each into the airbrush, and spray at around 25psi, building up layers untill the desired effect is reached.

I also use this mix and spray thin close spreaks moving fast with the direction of airflow, plus some sreaks of oil or dust and grime moving from top to bottom on the fueslage.

Many luftwaffe aircraft had these weathering patterns on the real aircraft.

I did think about not scatching the decals in places because the main factory codes, swastika and german croses were from what i see from photo's were freshly restored.

I did the same with the ju88.

So as you can see i got a bit carried away, all i did next was glue on all the bits and pieces, sorted out the seatbelts and glued on the canopy.

I finished off with 6 exhaust stains and mig pigments rain stains. Also i put the wiring that connects the two aircraft electrical systems, fuel line and control linkages.

After all that i have completed a very imposing aircraft that i have'nt any clue where to put it But it has been a very intersting build, and thinking about it, majority of the build was measuring to get it all to sit right.

But it has been a very intersting build, and thinking about it, majority of the build was measuring to get it all to sit right.

Anyway to the build, i have loved every minute of this project, the history too, even though i smashed the cradle off twice and had a couple of other minor problems. I really hope you enjoy the pics aswell, as i'm not a very good photographer . I also want to thank everybody for the very kind words and comments that people have put, and the much needed help when i havn't got a clue what i'm doing, so thankyou all

. I also want to thank everybody for the very kind words and comments that people have put, and the much needed help when i havn't got a clue what i'm doing, so thankyou all

Well that's it finally done, i hope you enjoy thanks for looking in guys