1/32 Revell Lynx conversion to AH7

By Tony Cooke

For my second Revell 1/32 Lynx (first one was a test shot build review for Airfix Model World mag (Jan or Feb issue), I have decided to make a proper Lynx and not one of those butt-ugly navy types. This one will be an Army AH7. A fairly simple mod from the German Mk88A.

Advantages to the Mk88A - Non folding tail boom, nose profile (non-FLIR) is the same as an AH7 (minus the radome), clockwise newer tail rotor and similar engine cowlings (minus a couple of small lumps).

Scratch building the following - Skids, instrument panel and using the kit nose as a basis to remodel and recast as an AH7. Will need to shift one of the cabin door windows to the front of the door as opposed to the dipping sonar role the Mk88A has in the kit and fill the forward flot-bag recesses. I’ve already removed the flanges where the sponsons sit too. Apart from that, tis a straight forward build.

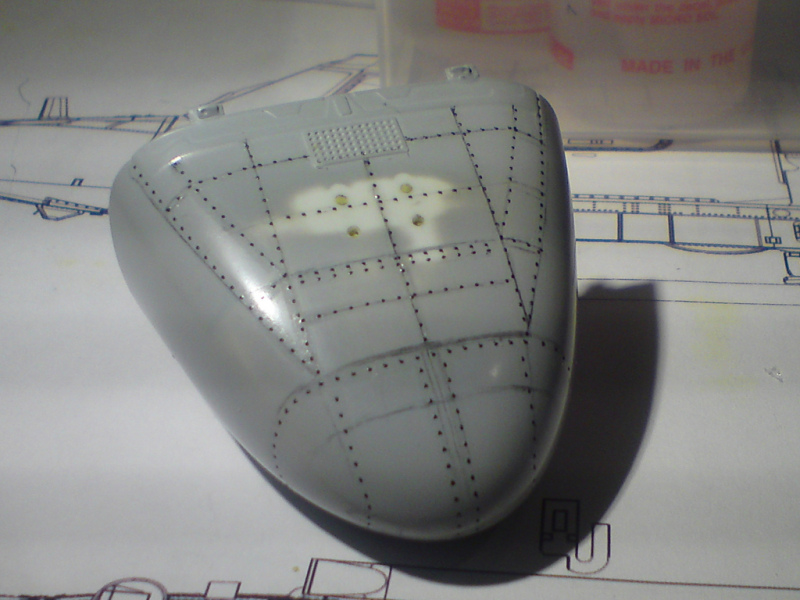

Made a start on the nose. I resin cast the top section of the nose (as the nose from front to about mid way back is horizontally symmetrical) then using the newly cast part, attached it to the lower section. I removed the rear section of the lower nose part and used that minus the radome. I filled the round hole with milliput and spend quite a while sanding, priming and shaping until it was the correct profile on the underside. I have a highly detailed pdf 3 view of an AH7 and scaled that up to 1/32 and printed them off. These are my templates to ensure everything is to scale. Once I was happy with the nose profile, I added Archer #30 rivet decals (as recommended by IIking on his 1/32 build) and will recast the whole nose out of two part resin. After that, I can work the newly cast nose with appropriate panel lines and will cut it up to make the nose avionics bay doors to show interior detail (means I will also have a master cast and mould for an AH7 ;-) ). I will be dismantling various useful bits from my Accurate Armour 1/35 Lynx to furnish this job. Some of you may remember my ‘progress’ on that nightmare of a ‘model’. Its never ever ever going to get completed so I hope I can make use of that £140 paper weight!

Heres the progress:

I filled and redrilled the nose upper antenna holes as they sit slightly further forward on the AH7.

I’ve recast the nose but it will need some further work as the .2mm Archer rivets didnt show up to well on the resin cast. Have ordered some .3mm rivets so will see if they give me better results. As well as that, my mould had too many air bubbles in it and is awkward in shape to give me satisfactory results. I’m thinking of doing the nose in several parts so that may help in the mould scheme. My aim is to open the nose avionics bay doors so I’m thinking that doing it as per the Airfix nose parts may be the way ahead.

Initial casting of the new nose. Lego is a perfect structure to use as a mould frame. I’ve lined it with 2 layers of cling film to make it water tight. I’ve used a wooden stick as a frame to suspend the nose in the cast.

Lower fuselage mods consisted of filling the harpoon deck lock cavity to the rear, filling the landing light hole (AH7 has its landing light under the nose), fabricating a new Rad alt panel which luckily covers the round hole where the sonar would come through and applying thin plasitcard to fill the area where the nose wheel faring would sit. I will need to remove the IFF small antennas too. Pencil lined the rear area where the rear skid posts will sit. The front skid posts will attach to the forward triangular shaped fillets.

Enhancement of the rear cabin area adding a few bits of millput to simulate flaps and hatches in the sound proofing. I also had to make the ‘broom cupboard’. I cut a rectangle out of the rear wall then made a box then mounted the cut out bit on to that.

I drilled the hydraulic pack inspection window and accumulator window out. I will place some thin clear acetate on the inside and apply the decal provided inside the housing on a box simulating the hyd packs. Still debating whether to cut the front fairing away and have it slid forward to display geatbox, AC gennies, hyd packs and all the other gubbins up there…..

Removed and filled the scoop on the right side of the fuselage. Only one on the Mk7 on the left. You can see where I’ve cut off the sponson mounts and will fill this area once the fuselage halves and floor are in position.

Modified cabin floor. I removed the rails on the rear left where the sonar operator seat would go. I’ve also removed the harness connector for the power for the sonar station at front right. You can still see the large circular raised section in the centre that would be for the dipping sonar. I’ve decided to leave this as I’ve going to put a wooded 3 piece cargo floor in and a six man seat.

Tail boom mods included cutting out the IGB covers (I will do as I’ve done on the Airfix Lynx and use fine mesh in these area). I’ve also learnt from my previous Revell 1/32 Lynx build and attached a brass rod to attach the horizontal tail stab as the kit pin is not up to the job. I’ve also cut about 10mm from the end of the stab too as the kit one is far too long. I’ve drilled out various holes on the boom and removed the VOR antenna mount midway along the tail boom. I will start to stick Archer rivets all over the tail boom once my new supply arrives.

I’m using a few bits from my now defunct Accurate Armour 1/35 Lynx. One part is my recast panel. Luckily the size is perfect.

The Mk88A Lynx has a couple of extra bulges on the engine cowlings so these were shaved off. You can just about see the area (grey on top middle). Because after shaving, the plastic was very thin, I applied a blob of superglue on the inside. I also drilled out the rear of the cowlings and will apply mesh here too.

Cabin roof has had a bit of treatment too. I’ve drill 12 holes just behind the cabin light and these will hold the pax drop leads. I’ve also cut out a rectangle to the front and put a square of thin plasticard on the top part. This will be wear the NVG wander lamps will go. I’ve also drilled a couple of holes for the front seaters drop leads. Yep, love this scale…I can go mad on detail

Again, seats (and SA80 Carbines) I made for the AA 1/35 Lynx will fit perfectly in this one.

Nose avionics bay detail. The shelf and housings are a bit small but will retrieve the avionics and fit them in the new nose.

Casting of the skid uprights and end caps. I will use brass rod for the main part of the skids, drill and pin the uprights and secure the resin cast end caps.

A couple of pics of my completed Revell 1/32 Lynx. .

Ok here’s the skids so far. All just dry fitted for now and I’m very happy even in this state how good they appear to be in symmetry, robustness and look.

Initially used plastic tube for main part of skid but have now elected to go for brass. The gaps between the skid posts and skid will be filled with a bit of milliput/filler.

I decided to drill carefully all the way through the front skid post and insert a .8mm brass rod that goes all the way through the skid tube too. Should be tough enoug and allow for a bit of flexibility for adjustment and strength. You can see the end cap and how I intend to attach it to the skid tube (just blutac inside for now but will fill it with milliput then insert the pin and adjust to central position before it sets. Luckily the fit is good enough that it sits flush and will require minimal filling on all four..

How I intend to attach the skids. As I mentioned before, the forward attachment points will utilise the triangular recesses (I will put the fillets in then drill the correct position). For the rear mount, I cut out a trough that will allow the raised upper area of the rear skid post to sit flush with the underside. Once in position, I will pin in place. The rear skid post has a .8mm hole drilled and pinned to the brass skid tube. Luckily, the rear skit posts are quite flexible and robust so will not require strengthening as per the front posts. I will blend the upper inner section of the skid post to the fuselage once in position as on the real thing, it disappears in to the lower fuselage.

General positioning and form is good and will require minimal adjustment once fixed in place.

All the cockpit and cabin bits have been primed so will set to work on those tomorrow. Once the nose issue is sorted, this shouldnt take too long…….so long as I dont decide to scratch build a couple of engines and open all the panels up.

Ok, update. Cabin complete. Just need to stick all the bits in. I used the 6 man seat from the AA Lynx as a template.

I also sliced the kit seat mounting rails off the seats and modified them to accept my scratch built armoured seats. And yep, Revell have modelled the pedal position correctly (right pedal forward on each side). We place the pedal forward when we shut down so it off loads the spring bias unit in the tail so it doesnt smash an engineer in the face if he’s working on it.

Even though I have said I’ll do it as a late 90’s Lynx serving with 655 Sqn in NI, my scratch built SA80 Carbines aren’t strictly accurate to period. We’ve only just started using those as personal weapons and the correct weapon should be the HK53. Also stowed on the seat but instead of fitting on the inner facings of the seats, were stowed inside the seat wings. Bloody uncomfortable to fly with as they would dig in to your left shoulder! (I used to chuck mine in the side map stowage….)

Start of the GPMG mount base plate. I’ll use the Airfix mount as a 3D guide.

I’ll be using the beautifully detailed Live Resin M240B converted to good old Air Role GPMG (removed lightweight barrel guard and various other yank-isms and redid the gas parts and return tube). Strictly speaking, its 1/35 scale but as you’ll see from the scale plans I’ve drawn up, its pretty much bang on. I’ve just learned that they have now released the M240G GMPG which is more of an equivalent of our GPMG. Plus you can now get spare barrels, link and a few ammo boxes. May well have to invest in a set or three cos they are so nice.

The GPMG mount base plate is ambidextrous on the real thing. The base plate can be fitted on either or both sides simply by flipping it upside down and redressing it with the fittings. In NI, we tended to have it on the right by default. The peculiarity of this was the aircraft commander would have to sit in the right hand seat as he has to have line of sight of any targets and clear the gunner to brass them up. Even though the commander usually sits in the left seat, we changed seats because the previous GPMG mount fitted could only be fitted on the right. A bit of a legacy keeping seating positions even when we fitted the newer ambidextrous mount.

GPMG mount complete, Fast Rope Frame complete, modified left hand cabin door complete.

The Mk88 kit has the sonar operator type left hand cabin door. The difference is the window hole is set to the rear of the door as opposed to the standard forward set. Looking at Spences progress on the HAS3, that kit has both the standard doors so once I get my mits on one of those, it should save me all this trouble of moving a hole!

You can see on this picture how the window hole differs on each door. The one on the left is the stbd door with the window hole set forward and the one on the right, the port door with the window hole set aft. I carefully cut the hole out.

Removed it.

Then rotated the cut out by 180 degrees.

Finished port door filled and cleaned up. The one on the left is a resin cast of the door. Not perfect but has come out reasonably well. As I mentioned, I’ll just wait til I get a HAS3 and use the correct door! An exercise in moving a hole if nothing else…..

I decided to order a slightly more representative GPMG as opposed to using my converted M240B. This one is the M240G. Live resin do actually do an FN MAG which is spot on but I cant find them in stock anywhere. Only real difference is the flash eliminator. On this one its slightly shorter than the standard one on a GPMG that we use. I can live with that,,

Gun mount parts. Brass case catcher, pintle and alloy mount. I’ve built it so it will function in movement correctly.

Ammo box. I made it from two standard 200 round 7.62mm boxes and dressed it with random bits of PE.

Mount base and link/brass drum. (I’ve just loosely attached the ammo box and my old GPMG to it for now)

In situ.

You can start to see on the upper forward part of the cabin roof, the NVG spot lights I’ve made and fitted.

Cabin roof with pax drop leads and NVG spot lights with umbilicals.

Fast Rope Frame that will be fitted on to the left hand NATO flange (the standard flange that TOW or any other role kit can be fitted)

Started off by selecting suitable cross sections of tube, I beam and H beam plastruct. The NATO flange (dark grey item) is from the AA kit).

Drilled appropriately and dressed with random bits of PE.

To ensure its sturdy enough, I’ve drilled .5mm holes and pinned the major parts as well as doing this to attach it to the NATO Flange and how that attaches to the side of the aircraft.

Just need to add a few Archer rivets to the base part of the gibbert. Need to make the block and tackle for the rope. I got hold of some scale tow rope and its perfect for the rope itself!

Currently working on the nose. Its giving me a few headaches as I want the finished article to have opening avionics bay doors. Quite a task turning a solid resin cast nose in to several sections. It will require me recasting a whole nose several times, slicing the forward part of the nose off, slicing the bottom section off, making the top panel and then the doors. I’m going through silicone rubber mould solution quicker than the FX guys on the Star Wars set at present!

Ok, so where are we so far? Fuselage is now together, tail boom together. New AH7 resin nose recast and am happy with how its now turned out. Resin cast skids complete. IRCM exhausts resin cast and nightmare of all time consuming (but bizarrely therapeutic) things - applying thousands of rivets!! I think I can now be accused of being a rivet counter.

I decided to drill out the Intermediate gerabox. Past experience of doing the Mk88A like this made me aware that even with mesh on, it leaves an empty space inside where the actual IGB would go so I decided to dig out the mould I made for my AA Lynx and recast an IGB. The green rod is the support strut.

Tail boom together with mesh and IGB fitted. Cant see much of it but I know its there!

Cockpit and cabin area looking nice and busy. Will complete it with nav bags, ammo boxes and a few bits of role kit to give it a bit more life.

Enhanced a few areas with mesh such as the engine cowlings.

Main gearbox oil cooler.

I drilled out the port and sbd hydraulic pack inspection windows (just a decal on default kit). To give it depth, I constructed a little box inside and painted and mounted another little box then placed the kit (hydraulic level)decal on the hyd pack. Once main painting is complete, I intend to use Humbrol Clearfix to the round hole to make the window.

Nose Flotation bag insert filled.

Rear sponson cut out initially backed with thin card then thin layer of milliput was applied to fill the gap. You can see how I intend to attach the rear of the skids. I cut out the slots to allow a slight recess. I then ‘strapped’ an alloy tube in the centre of the recess to facilitate the rear skid uprights to be pinned in to the tubing. Once in situ, I’ll flush the top of the skid pots with the lower fuselage. I have made a ‘plug’ for the large square recess where the deck lock mechanism would usually fit on a Naval airframe. I filled it with milliput then popped the box out then made a mould and cast it so I have copies of the plug for subsequent versions. (did the same for the landing light housing. AH7 has it under nose)

Becuase I’m doing this Lynx with the IRCM exhaust bins, I had to remove the rear area of the engine deckings then cover it with thin plasticard.

And now the fun begins!!!! (you can see where I’ve applied milliput to the sponson cut-outs. The other bit of milliput on the side of the fuselage is where Ive removed the cooling scoop that is only on the left side of the AH7)

On skids for the fist time. IRCM bins and fluted exhausts dry fitted at the moment.

This view shows the new nose I cast. Really happy with it now despite it causing me a few headaches! Youll notice the recast single piece skids now. I inserted a brass rod at each of the skid posts to add strength and allow for small bits of adjustment if needed. As it sits at the moment with them just dry pinned in to the fuselage, there is only a .5mm difference in height from what it should be. Better tolerances than Westland……

Its starting to look like a proper Lynx now :-D

Next area of work will be masking inside of windscreen (Eduard are due to release a mask for this kit very soon) then fit it to fuselage. I’ll start the priming process which will let me see how realistic the rivet effect has been. It had better be bloody good cos it took me 5 days to put them all on!!!!!!

Airframe primed and base layer of grey applied. Most ancillaries and role kit complete. Only major work required is airbrushing green camo and final assembly of skids, tail boom and other odds and sods.

Ok, a couple of pics of a few things. Decided to make the right hand footstep with BriteStar IR lamp that is fitted to the front of the right hand skid. We generally didnt fit the standard left footstep as it was pointless.

Made using 1mm round plastic and .4mm sheet

IRCM exhausts recast and finished with brass sheet cut and placed for the exhaust baffles.

Role kit (Fast Rope Frame and GPMG and mount) complete.

Antennas complete

Ice accretion meter (two bars on the right hand side outer cockpit wall) complete

Airbrushing of green complete. I used a mixture of Vallejo Model air colours and am extremely happy with the colour and results. First time I’ve used Vallejo through my airbrush and like them a lot.

I’ve made my own decal set too and after extensive testing, am happy with the results

Ok so here’s some piccies;

Added a bit more detail to the head including scratch building the MRHVA (bonk) and adding bonding leads to each pitch change rod. You’ll notice I’ve added brass rods to the extension arms. This allows me to slide and clip each blade in place without the need to glue them. Means its easy to transport and adjust to correct position.

Added some more detail to the tail rotor. Stuck a nut on the end of the pitch change bridge and drilled 0.3mm holes to each blade root and added two tiny little bolt heads to each blade attachment. Also replaced the moulded mass balance rods with 0.6mm brass rod. I decided (as I always do) to hand paint the red and white and leading edge bits as opposed to using the decals.

Right hand footstep with BriteStar IR lamp.

Just roughly pinned in place on the skid for now. Top of the footstep is some random but perfectly sized PE from the spares box.

I constructed the lamp by making a box from plasticard then with some spare PE for the front face, placed some 0.3mm clear sheet inside after painting the inside of the lamp gold and orange.

Fast Rope Frame on NATO flange. The rope is some copper scale tow rope. Really nice and flexible. Sprayed a suitable rope like green. The coiled section will live under the six man seat.

Slight bit of OCD in that I constructed the Quick release shackle as per the real thing. I resisted actually making it quick release by pulling the release pin! The part where the rope attaches is alloy tube flattened and drilled at the top then pinned to the QR shackle by way of a 0.4mm pin. Once the whole FRF is fitted to the aircraft, I’ll position the rope accordingly (as I mentioned, the ‘rope’ is very flexible).

GPMG and mount complete. And yes, I’ve painted the butt number on the Gimpy too….

As some of you may remember from my previous Lynx builds, I’m a bit particular to getting the green correct. In my opinion, This is the best match I’ve made so far. It may look a little light in the photo but to my eye its almost perfect. With gloss and matt varnish coats and Flory weathing to go on, it should give it the correct hue.

This picture really brings out the rivets. I was worried they’d be too much but they look nicely to scale. I used the blu-tac and mask technique to apply the green and was worried that some of the rivets would lift once I demasked. Luckily only a couple of tiny areas suffered and wont be noticeable once weathered and covered in the usual Lynx grime and oil. I added the rear RWR mounts to the mid aft of the fuselage (naval variants have them mounted differently).

My decal sheet. I’ll use a combination of the Revell sheet and my own. In the kit sheet, the walk areas are grey but on Army Lynx they are black hence why I’ve done my own. I’ve also thought ahead a bit and added RM stencilling and the spotters amongst you will notice some AH9/AH9A serial numbers ;-) . I’ve also done the ETPS markings but white doesnt come out very well on the print. I’ve also added 655 Sqn crests and 671 Sqn crests. After quite a bit of testing, I’ve got best results using Laser paper in a laser printer then sprayed Tamiya semi clear varnish over the sheet to protect them. I tried hand brushing the suggested liquid decal set on the sheet but it makes the film too thick. Whites and yellows dont come out too well either and the recommendation is to pass the sheet through the printer a second time. Not too sure if this would work on a laser printer?

Bored at the moment waiting to apply clear varnish so have distracted myself with something else. IRCM exhausts now complete and weathered

I’ve decided to make a bloke too. Made his nav bag (US style helmet bag) out of milliput and am quitr pleased with how it initially looks. I’ll stuff it full of maps, crap and some sarnies later.

I think the main figure was from Legend, the head is from Hornet and the NVG are from Live Resin. I’m going to convert the helmet from a US Alpha helmet in to a Mk4B 4. I’ve already scooped out the head that was in there and removed the visor array. I’m going to place the NVG in the stowed position on the helmet and prob leave the the helmet on one of the front seats or if I can still access it, hang it up above the windscreen frame on the inside.

Fantastically detailed NVG from Live Resin

And fantastically detailed head from Hornet.

Ok so have now completed the chap and his kit. I decided to paint two heads so I have a choice (and also a bit of practice as I’ve not painted figures before). I’ve managed to drill and pin the heads so I can swap them if I get bored. I’m happy how the Mk4 helmet has turned out. The eagle eyed amongst you will note he’s not wearing a UK issue grow-bag or LCJ but a bit of artistic license is allowed.

Head #2

Mk4 helmet

Need to attach an NVG counter weight to the rear of the helmet.

Need to sort out the frayed end to the mic-tels lead.

I’m thinking of positioning him near the cockpit door looking up towards the main rotor head having just dumped his kit in the cab.

Tempted to start doing figures as it seems very rewarding.

Gloss varnish applied so am just waiting for it to go off. Should get cracking on decals this evening.

Sorted a pose out for my chap;

I made a little set of FRC’s (Flight Reference Cards) and printed a load of minature maps off to stuff in the nav bag. And yep, OCD kicking in. The FRCs are actually Lynx AH7 and I put little ring ties in them and the large map sticking out the bag is a 1-250,000 of South Armagh…..(I’ll prob stick this on the dash behind the windscreen gash style). I might write some crap on the knee board if I can miniaturise a chinagraph…